.png)

Packaging

When it comes to ensuring that your wire’s quality is preserved during shipping process, Fort Wayne Metals offers a wide variety of packaging options. We give you the option to specify the spool type you prefer from our wide variety of options, or we can recommend the spool type that we believe would work best for your specific needs.

Due to the fact that some alloys are subject to corrosion, we add desiccant packets to the bags in order to provide additional protection of the wire.

Straightened and cut wire is shipped via PVC tubes or wood crates, depending on the quantity.

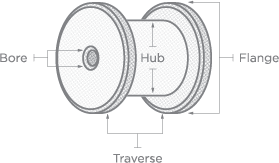

| Spool | Equivalent | Flange | Hub | Traverse | Bore | Max capacity* | Diameter | Spool composition |

|---|---|---|---|---|---|---|---|---|

|

55.88 cm x 27.94 cm |

-- |

55.88 cm |

35.56 cm |

27.94 cm |

12.7 cm |

204.1 kg |

0.762 mm - 3.66 mm |

Polystyrene |

|

45.72 cm x 25.4 cm |

-- |

45.72 cm |

27.94 cm |

24.38 cm |

12.7 cm |

68.03 kg |

0.762 mm - 3.66 mm |

Polystyrene |

|

30.48 cm x 15.24 cm |

-- |

30.48 cm |

15.24 cm |

15.24 cm |

3.3 cm |

27.21 kg |

0.304 mm - 1.524 mm |

ABS |

|

Weld wire |

-- |

29.72 cm |

21.08 cm |

9.2 cm |

5.08 cm |

13.60 kg |

0.102 mm - 1.27 mm |

ABS |

|

20.32 cm x 8.89 cm |

-- |

20.32 cm |

11.68 cm |

15.24 cm |

3.048 cm |

11.33 kg |

0.304 mm - 1.524 mm |

ABS |

|

15.24 cm x 8.89 cm |

-- |

15.24 cm |

8.89 cm |

8.89 cm |

1.575 cm |

4.54 kg |

0.076 mm - 0.508 mm |

ABS |

|

34.59 cm x 9.017 cm |

-- |

34.59 cm |

28.34 cm |

9.017 cm |

5.08 cm |

6.803 kg |

0.0508 mm - 0.762 mm |

ABS |

|

11.43 cm x 7.62 cm |

-- |

11.43 cm |

6.35 cm |

7.62 cm |

1.57 cm |

1.133 kg |

0.076 mm - 0.254 mm |

ABS |

|

6.35 cm x 7.62 cm |

HK 76-45 |

6.35 cm |

4.318 cm |

7.62 cm |

1.57 cm |

0.453 kg |

≤0.177 mm |

ABS |

|

HK 76-45 |

6.35 cm x 7.62 cm |

6.35 cm |

4.445 cm |

5.994 cm |

1.57 cm |

0.453 kg |

≤0.101 mm |

-- |

|

DIN80 |

-- |

8.128 cm |

5.08 cm |

6.35 cm |

1.60 cm |

0.453 kg |

≤0.0762 mm |

ABS |

|

DIN100 |

-- |

9.606 cm |

6.35 cm |

7.874 cm |

1.60 cm |

1.360 kg |

0.0254 mm - 0.127 mm |

ABS |

|

DIN125 |

HKV 125 |

12.446 cm |

7.874 cm |

9.906 cm |

1.60 cm |

2.267 kg |

0.101 mm - 0.254 mm |

ABS |

|

HKV 125 |

DIN125 |

12.496 cm |

7.112 cm |

6.502 cm |

1.60 cm |

1.360 kg |

0.101 mm - 0.254 mm |

-- |

|

DIN160 |

HKV 160 |

16.002 cm |

9.906 cm |

12.7 cm |

2.209 cm |

4.54 kg |

0.254 mm - 0.508 mm |

ABS |

|

HKV 160 |

DIN160 |

16.002 cm |

8.99 cm |

8.509 cm |

2.209 cm |

4.54 kg |

0.254 mm - 0.508 mm |

-- |

|

DIN250 |

-- |

24.892 cm |

16.002 cm |

16.002 cm |

2.209 cm |

9.071 kg |

0.304 mm - 1.016 |

ABS |

|

Wardwell bobbin |

-- |

6.604 cm |

3.302 cm |

7.112 cm |

2.794 cm |

0.226 kg |

≤0.0762 mm |

Nylon |

|

Medium braider bobbin** |

-- |

4.267 cm |

2.578 cm |

2.641 cm |

1.054 cm |

0.113 kg |

≤0.0762 mm |

Acetal Copolymer |

|

Larger braider bobbin** |

-- |

3.987 cm |

2.971 cm |

2.641 cm |

1.054 cm |

0.054 kg |

≤0.0762 mm |

Acetal Copolymer |

|

New England #2 |

-- |

4.318 cm |

1.574 cm |

6.35 cm |

0.762 cm |

0.340 kg |

≤0.127 mm |

Nylon |

|

Endura® bobbin** |

-- |

4.292 cm |

2.590 cm |

3.556 cm |

1.054 cm |

0.090 kg |

≤0.0762 mm |

Acetal Copolymer |

|

* Actual capacity varies with wire size and alloy type. Please check with your Customer Service Associate for details. |

||||||||

Endura® bobbins

The Endura® bobbin's angled flange design avoids wire pileup during spooling, minimizes contact of the wire with the flange during pay-off and removes the potential for flange toe-in. And each spool is carefully manufactured in order to provide smooth surfaces with no snag points. Many Endura® bobbins are designed to simply replace their conventional counterparts, so switching will be quick and easy. If your manufacturing process could benefit from increased machine uptime, contact your Fort Wayne Metals representative and ask them to show you how Endura® bobbins will go the distance for you.

Labeling

An integral part of our packaging process is quality control through spool labeling. Standard information on a spool label include:

- Alloy type

- Size

- Lot number

- Spool net weight

- Customer purchase order number

- Date

- Spool number

- Ultimate tensile strength

- Average break load

- Percent elongation of the wire

Spool returns and recycling

In an effort to reduce our environmental footprint, Fort Wayne Metals offers a 50% refund of the deposit on our spools returned to us in good condition. (Please note that you will be responsible for freight charges.)

To qualify for this refund, a spool is considered “in good condition” when it meets the following specifications:

- Is free of wire scrap or other material debris.

- Has not been altered, including drilling new holes.

- Is not damaged beyond normal or reasonable wear.

While spool deposit refunds are not issued for returned Endura® bobbins, broken or damaged spools, and select spools due to their size or nature of use, Fort Wayne Metals will accept them as part of our Sustainability Initiative for recycling. We recycle the various spool compositions through manufacturers and other responsible vendors in order to reduce the volume of recyclable products being taken to landfills.

Please ship your spools directly to the Fort Wayne Metals Recycle Center. This will help minimize the environmental impact of sending products between facilities.

Fort Wayne Metals - Building D

4030 Piper Drive

Fort Wayne, Indiana 46809

All spool returns must include a packing slip detailing the spool type, quantity, and color for all spools included in the return.

Fort Wayne Metals encourages our customers to take advantage of the spool return program. Please reach out directly to your Customer Service Assistant if you have any questions about the spool return program or recycling options. To find out more about Fort Wayne Metals Recycling Program and Sustainability Initiatives, please visit the Corporate Responsibility page.