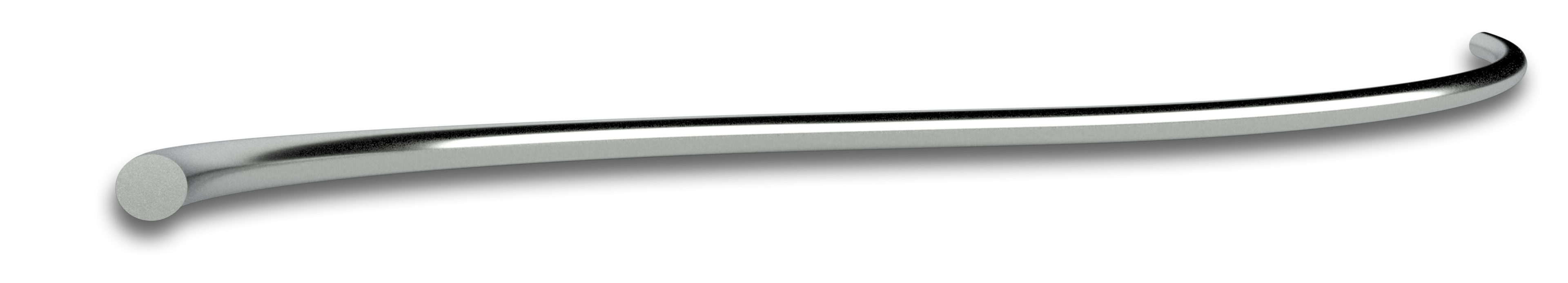

Understanding round wire

Round wire starts at a larger diameter and is expertly drawn down to customer specifications, all the way to ultra fine diameters smaller than a human hair. It comes in standard stainless steel, Nitinol, titanium, and other high-performance alloys that are customized to serve almost any application.

Typical end uses

Round wire can be used on its own, or as a component in strands, cables, mechanical assemblies, or other constructions that contribute to end uses such as:

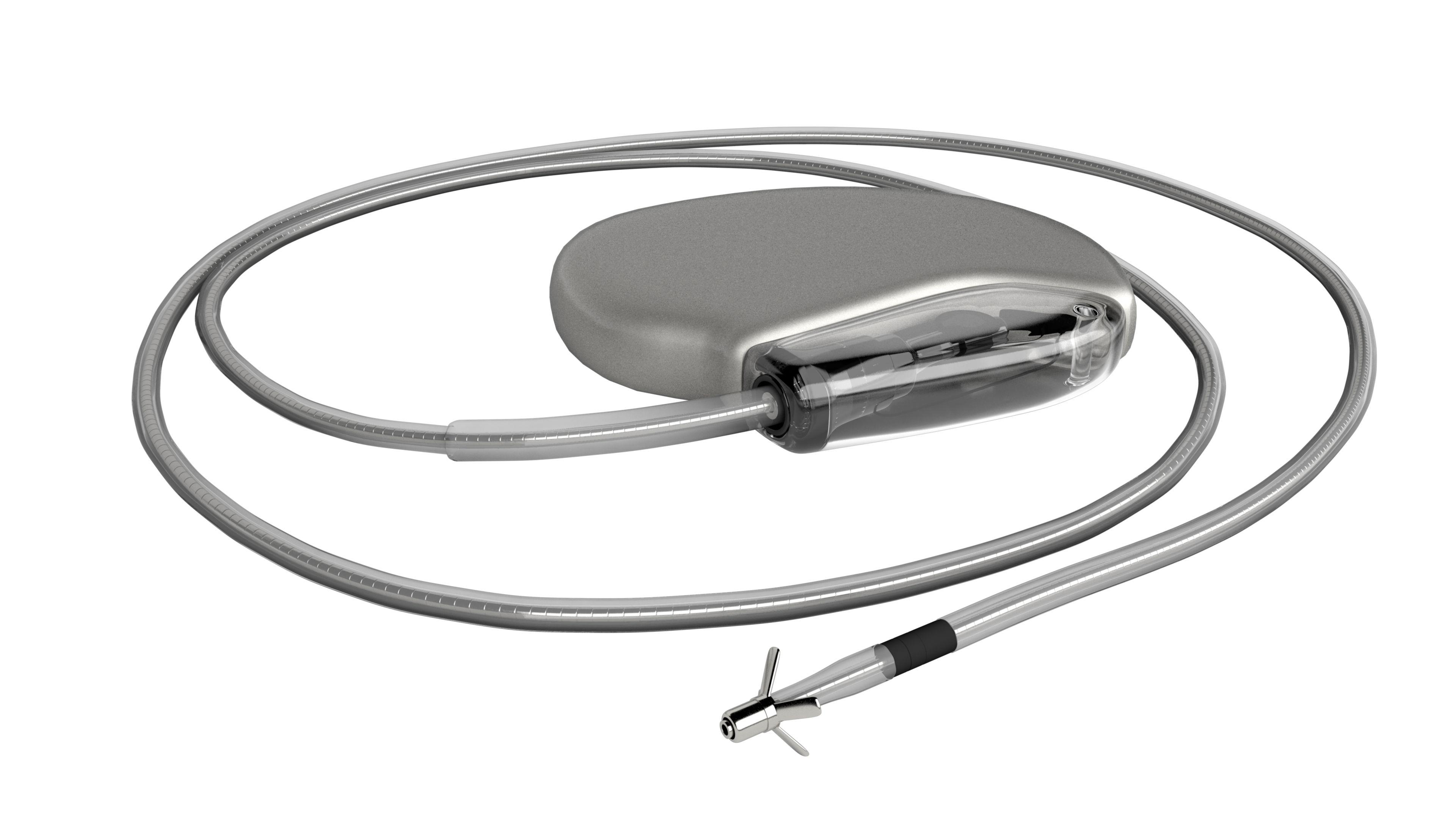

- Articulation devices

- Endoscopic devices

- Minimally invasive surgical instruments

- Pacing leads

Design specifications

The first step to creating custom round wire is choosing the right material. Click the links below to learn more about the benefits offered by our wide selection of alloys.

Size range

Round wire can be manufactured in diameters ranging from 0.0127mm to 13.97 mm [0.0005 in to 0.550 in].

Value-add services

Wire cleaning services:

If excess debris is a concern, we have the following options to consider:

- Hot alkaline clean diameters larger than 0.1016 mm [0.004 in]

- Isopropyl alcohol wipe all round wire diameters

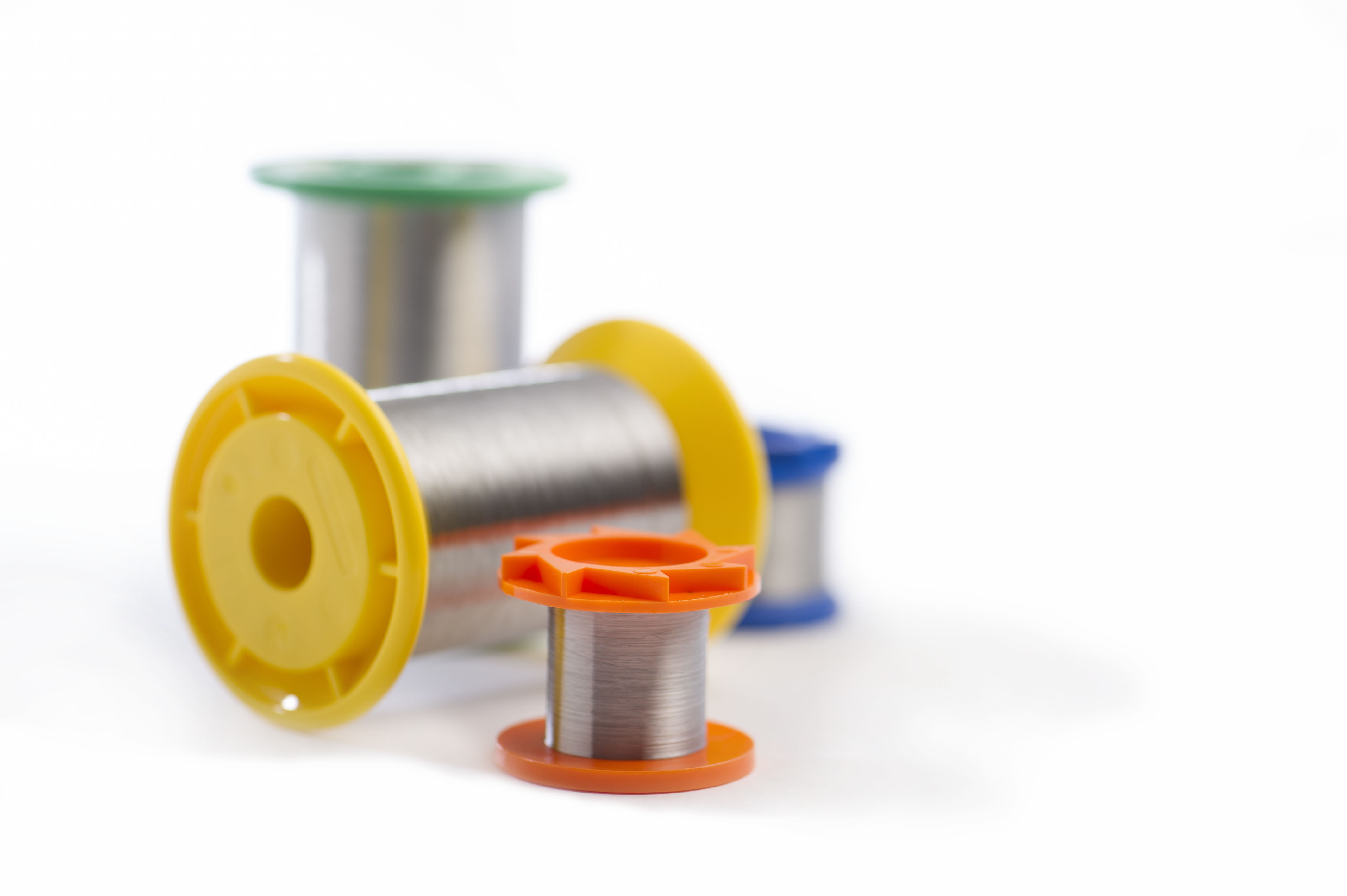

Multi-end spooling:

In addition to our custom spooling capabilities, we also offer multi-end spooling - processing multiple wires on the same spool. This option is especially popular for braiding applications, as it adds torqueability and stiffness to medical devices, such as catheters.

- Up to 9 ends for diameters ranging from 0.0254 mm to 0.0762 mm [0.001 in to 0.003 in] on Steeger style braider bobbins.

- Up to 9 ends for diameters ranging from 0.0762 mm to 0.205 mm [0.003 in to 0.008 in] on Wardwell or New England style braider bobbins.

Heat-treatment capabilities:

Stress relieving is a low-temperature thermal treatment used to relieve internal stresses and improve wire cast, mechanical performance, or both.

- Stainless round wire diameters under ~1.6 mm [0.063 in] and flat wire.

- Stress relieving is an ideal process when a relatively straight wire is needed, but full straightness is not required off the spool. For very straight wire, our SLT® wire is available off the spool or in cut lengths, depending on your end-use requirements.

- Not recommended for alloys with a significant heat treatment response, such as 17-7PH, 17-4PH, FWM™ 1058, FWM™ 1537, and 400 series alloys.

Every application is different. Let’s talk about your needs and how our round wire can support them. Connect with one of our technical experts for assistance.

Unable to load the form? Click the button below: