Understanding Nitinol

From robust melting capabilities to advanced processing techniques, we empower your vision with high-quality product offerings that advance devices ranging from stents and surgical implants to spacecraft and industrial valves.

With our recent ongoing investments and vertical integration, we have secured our Nitinol supply chain. We can provide you with:

- Advantageous lead times

- Fewer potential bottlenecks

- Higher quality control

- More stable pricing

- Ability to scale your operations or develop new products

Nitinol solutions

Whether you require the superelastic properties that support life-saving medical devices or the shape memory effect driving advanced industrial applications, we customize the right Nitinol construction to fit your application.

Nitinol melt solutions

We provide a fully integrated approach to Nitinol production, controlling every step from melting to custom finishing, ensuring consistent, high-quality material to meet industry demands.

Chemical composition

|

Element |

ASTM F2063 |

| Nickel | 54.5 – 57.0 |

| Carbon | 0.040 max |

| Cobalt | 0.050 max |

| Copper | 0.010 max |

| Chromium | 0.010 max |

| Hydrogen | 0.005 max |

| Iron | 0.050 max |

| Niobium | 0.025 max |

| Nitrogen | 0.005 max |

| Oxygen | 0.040 max |

| Titanium | Balance |

| All Binary Nitinol grades meet the chemistry requirements set forth by ASTM F2063 for use in surgical implants. | |

Nitinol products and solutions

Our range of customizable Nitinol products, from flat wire to complex custom shapes, can help advance your cutting-edge projects. And with advanced capabilities, we're equipped to deliver precision-engineered solutions for the most demanding applications. Partner with us to explore the full potential of Nitinol for your applications.

Surface finishes

We offer a variety of surface finishes so you can tailor our Nitinol to your exact needs.

- Pickled chemical removal of oxide layer along with a slight amount of base metal - surface will have a rough texture

- Etched chemical removal of oxide layer - will maintain smooth surface

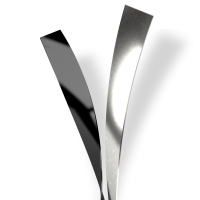

- Etched and mechanically polished chemical removal of oxide layer followed by mechanical polish - surface will have stainless steel appearance, although at > 40x magnification micro scratches are present

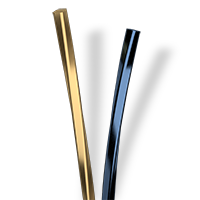

- Light oxide diamond drawn with a gold, amber, or dark brown surface color

- Dark oxide diamond drawn with a dark purple, gray, or black surface color

Additional capabilities

Our value-added services help you achieve more. Whether it's laser ablation and precision coatings or accredited materials testing and access to further research and development expertise, we have the capabilities to take your customized Nitinol further.

- Custom shapes in a wide variety of shaped cross-sectional wire

- DFT® wire manufactured with a Nitinol core or tube sheath

- HHS® tube, a hollow strand providing torque, pushability, flexibility, and control for complex navigation.

- Melting high quality raw materials carefully combined in a precision melting process

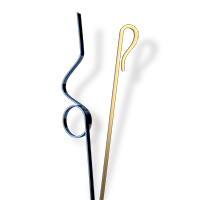

- Shape setting Nitinol wire formed to a specific geometry after undergoing strain

- Strands and cables complex constructions offering high strength, high fatigue, and flexibility

Unable to load the form? Click the button below: