R&D

- Aug 22, 2022

Superelastic conductor material with enhanced fatigue durability for implantable lead service

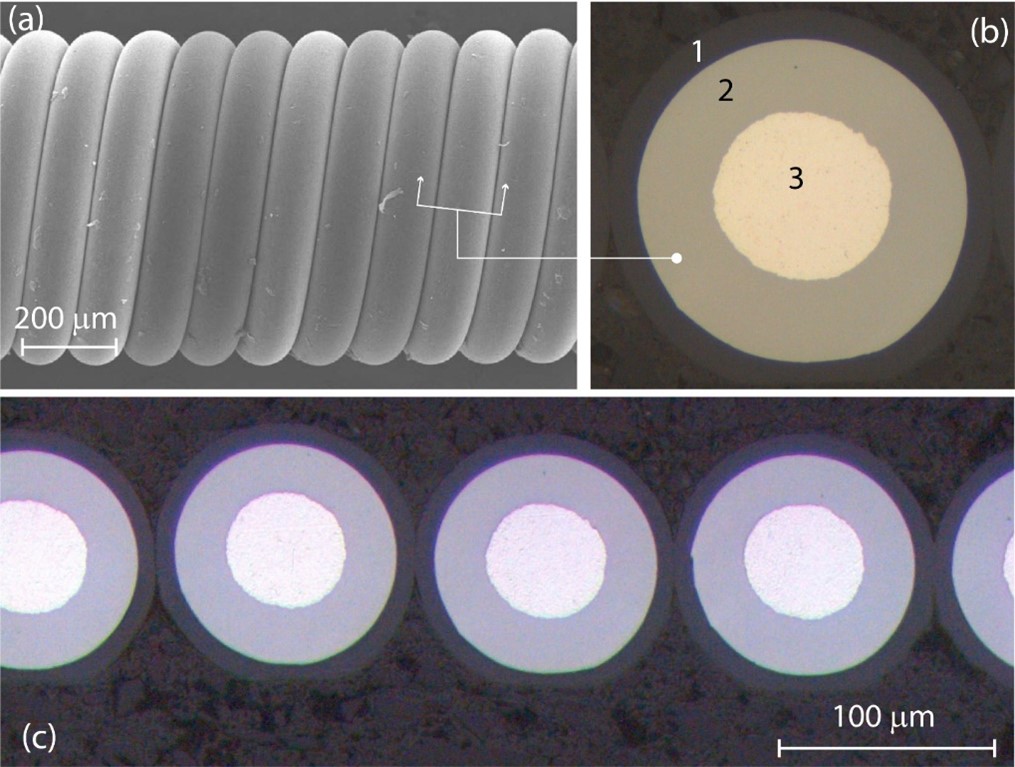

A new patent-pending technology to enhance the fatigue life of biostimulation leads used in devices like pacemakers, implantable cardioverter defibrillators, deep brain stimulators, and spinal cord and peripheral nerve stimulators is under development in Fort Wayne Metals R&D. Conventional leads employ a composite DFT® wire with a 35N LT® alloy shell and a conductive silver core. By replacing the 35N LT® alloy with superelastic or shape memory nitinol, dramatic improvements in strain-fatigue (and presumably service life) can be achieved. A polyimide coating is further applied to the wire, and with proper care can withstand the shape-setting head treatments needed to form nitinol into the desired lead components like cables and coil.

For more details and a look at some early results, please read our white paper. For more information, and to see if this technology could be beneficial in your application, please reach out to the team at [email protected].

If you have questions, or want to know more about other projects and innovations, we'd like to hear from you. Please contact us: [email protected]

For more updates, visit our Library of Updates

Disclaimer: Our updates are sneak peeks of what our R&D department is working on. This is not meant to imply that we have what is referenced above ready for robust serial manufacture.