R&D

- Oct 1, 2015

Drawing Magnesium’s Strengths: Absorbables and Beyond

Adam Griebel, Research & Development Engineer

Magnesium is known mainly for its light weight, but in recent years it has received considerable attention for a much different reason: the ability to be absorbed by the human body. Being a necessary nutrient, the body has natural ways of breaking down metallic magnesium over time. This means that in many medical devices, the inert stainless steel or titanium currently used could be replaced by magnesium. Doing so would have the potential to reduce long-term complications and eliminate secondary procedures. It may also enable new applications that broaden the scope of medical treatment.

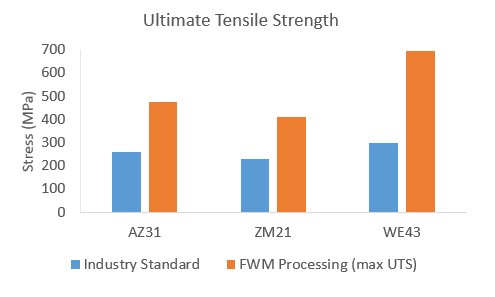

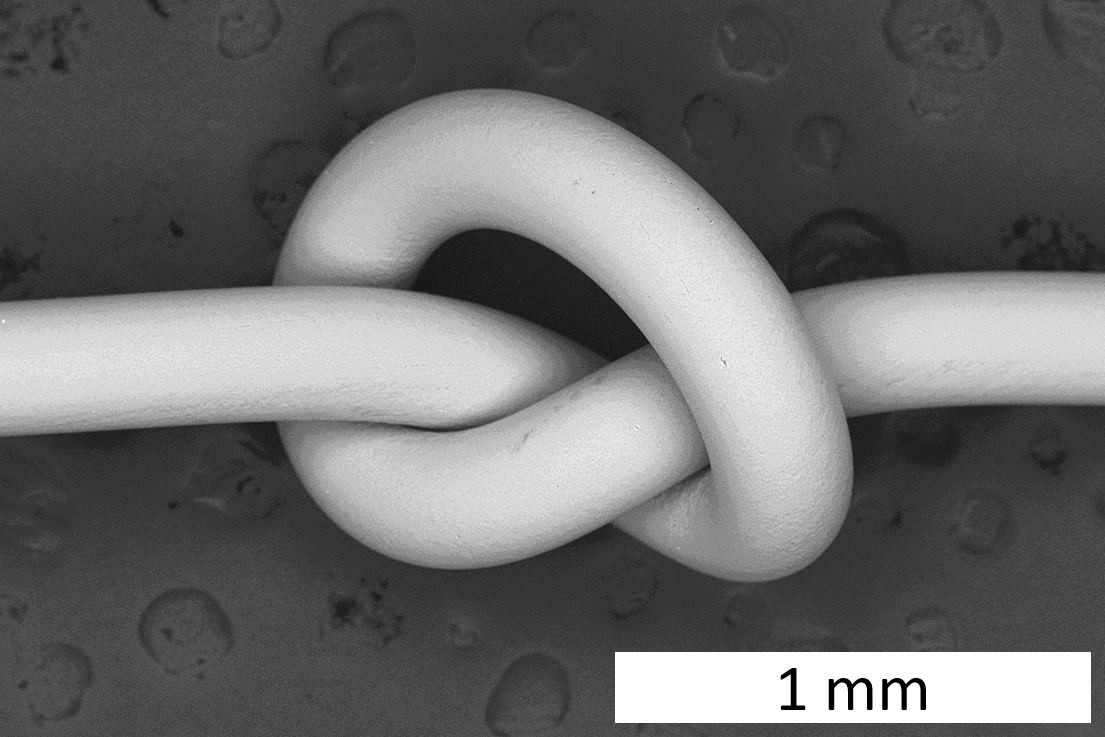

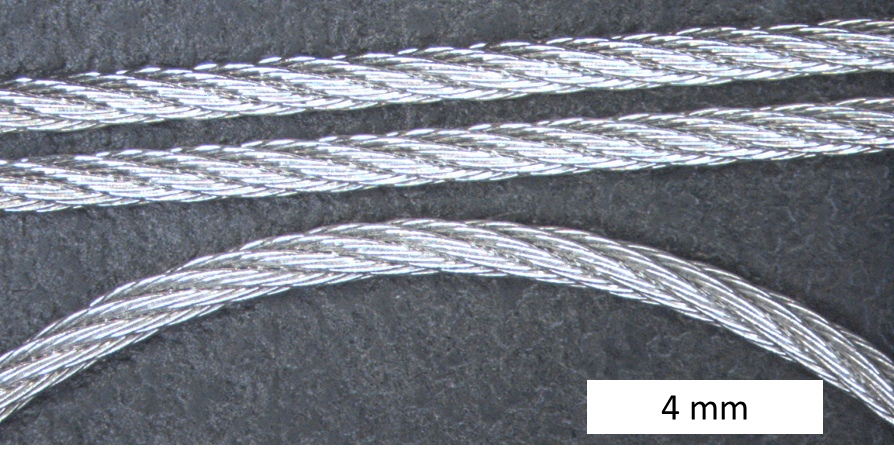

At Fort Wayne Metals, we’ve been applying our world-class wire processing to magnesium and magnesium alloys, with excellent results. We’re able to achieve bright surface finishes, ultrafine diameters (as low as 20 µm), and record-setting strength through work-hardening (Fig 1). We’ve done this over a wide range of magnesium alloys, while retaining ductility and toughness to withstand subsequent forming operations (Fig. 2, 3). Not only can these processes enable next-generation medical devices, there may be real applications in lightweight structures, welding, and additive manufacturing for the aerospace and defense industry.

If you’d like to read more about some of the work we’ve presented at technical conferences, see the references below. If you’d like more information or want to discuss your application with us, please contact [email protected].

Figure 1. Cold-drawing significantly increases tensile strength in magnesium alloys.

Figure 2. This 300 µm diameter magnesium alloy wire has sufficient ductility to be tied into a knot without fracture.

Figure 2. This 300 µm diameter magnesium alloy wire has sufficient ductility to be tied into a knot without fracture.

Figure 3. This 1 mm diameter 7x7 cable made from a Mg-Rare Earth alloy could find use in orthopedic fracture fixation.

Further Reading:

[1] A. Griebel and J. Schaffer, “Development of high-strength bioabsorbable Mg alloys suitable for conventional cold-working processes,” Eur. Cell. Mater., vol. 26, no. Suppl. 5, p. 2, 2013.

[2] A. Griebel and J. Schaffer, “Cold-drawn ZM21 and WE43 wires exhibit exceptional strength and ductility,” Eur. Cell. Mater., vol. 28, no. Suppl. 3, p. 2, 2014.

[3] A. Griebel and J. Schaffer, “Fatigue and Corrosion Fatigue of Cold Drawn WE43 Wires,” Magnes. Technol. 2015, pp. 303–307, 2015.

[4] A. Griebel and J. Schaffer, “Cold-drawn Mg alloy composite wires minimize risk through galvanic coupling,” Eur. Cell. Mater., vol. 30, no. Suppl. 3, p. 13, 2015.

Disclaimer: Our monthly highlights are sneak peeks of what our R & D department is working on. This does not mean we have what is referenced above ready for manufacturing.