Monofilament

wire

Shaped wire

Shaped wire allows you to leverage the versatility of non standard profiles. From triangles to crescent shapes, or wire with a continuous helical groove, we manufacture shaped wire in a variety of alloys. To do this, we use specialized tooling and processing, creating a unique construction that decreases the overall cross-sectional area.

Finding the right shape

We make a number of standard shapes, but we're always willing to push the boundaries. If the shapes below aren't what you're looking for, don't hesitate to reach out to a Sales Representative to start a conversation about custom shaped wire.

|

D-wire 0.0381 x 0.1016 mm [0.0015 x 0.004 in] to 1.016 x 2.032 mm [0.040 x 0.080 in]

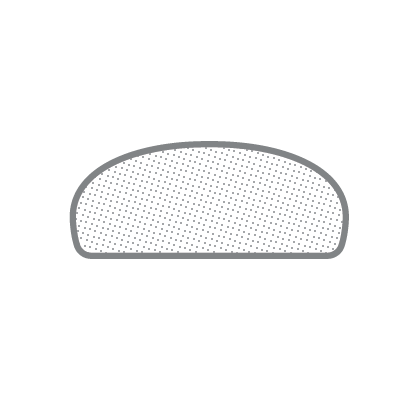

|

|

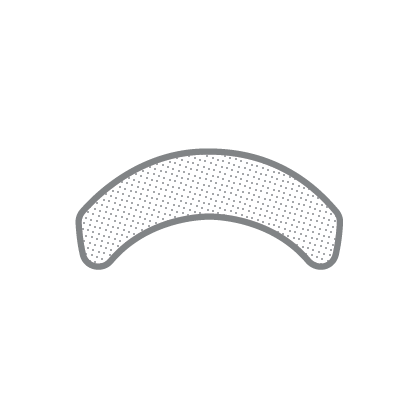

Crescent wire 0.147 x 0.254 mm [0.0058 x 0.010 in] to 1.016 x 1.524 mm [0.040 x 0.060 in] |

|

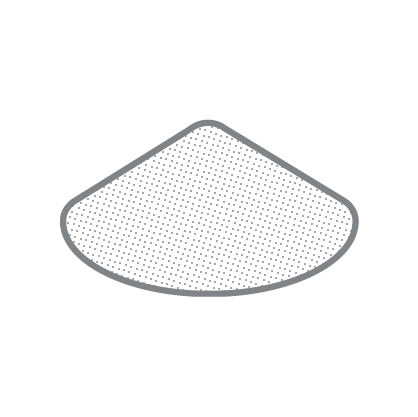

Pie wire 0.142 x 0.177 mm [0.0056 x 0.007 in] to 0.762 x 1.143 mm [0.030 x 0.045 in]

|

|

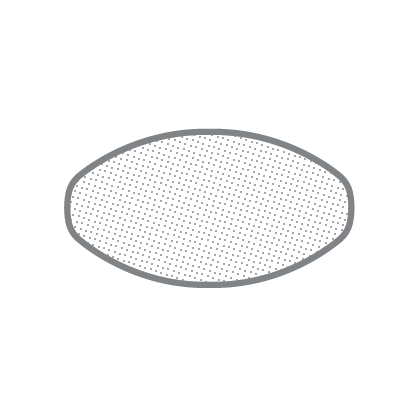

Elliptical wire 0.0254 x 0.0635 mm [0.001 x 0.0025 in] to 0.508 x 1.524 mm [0.020 x 0.060 in] |

|

Triangle wire 0.1143 x 0.216 mm [0.0045 x 0.0085 in] to 1.016 x 1.143 mm [0.040 x 0.045 in] |

|

Grooved wire 0.254 to 0.762 mm [0.010 to 0.030 in]

|

|

Turkshead wire 0.152 x 0.152 mm [0.006 x 0.006 in] to 0.889 x 0.889 mm [0.035 x 0.035 in]

|

Shaped wire is available in most alloys.

Common end uses

With so many different constructions, shaped wire finds use in a variety of end applications. We often see our customers use shaped wire in catheter wires where the unique shapes allow them to fit multiple wires for a single entry point within the same overall diameter.

- Catheter wires

- Shaped guidewires

- Staples

- Coiling applications

- Tooling

- Needles

- Deployment mechanisms

- Orthodontic wire

Custom services

We can supply shaped wire in cut lengths. We can also perform a number of other assembly operations to help you reduce process steps or eliminate in-house assembly needs. Ask your Sales Representative about customizing your shaped wire order.

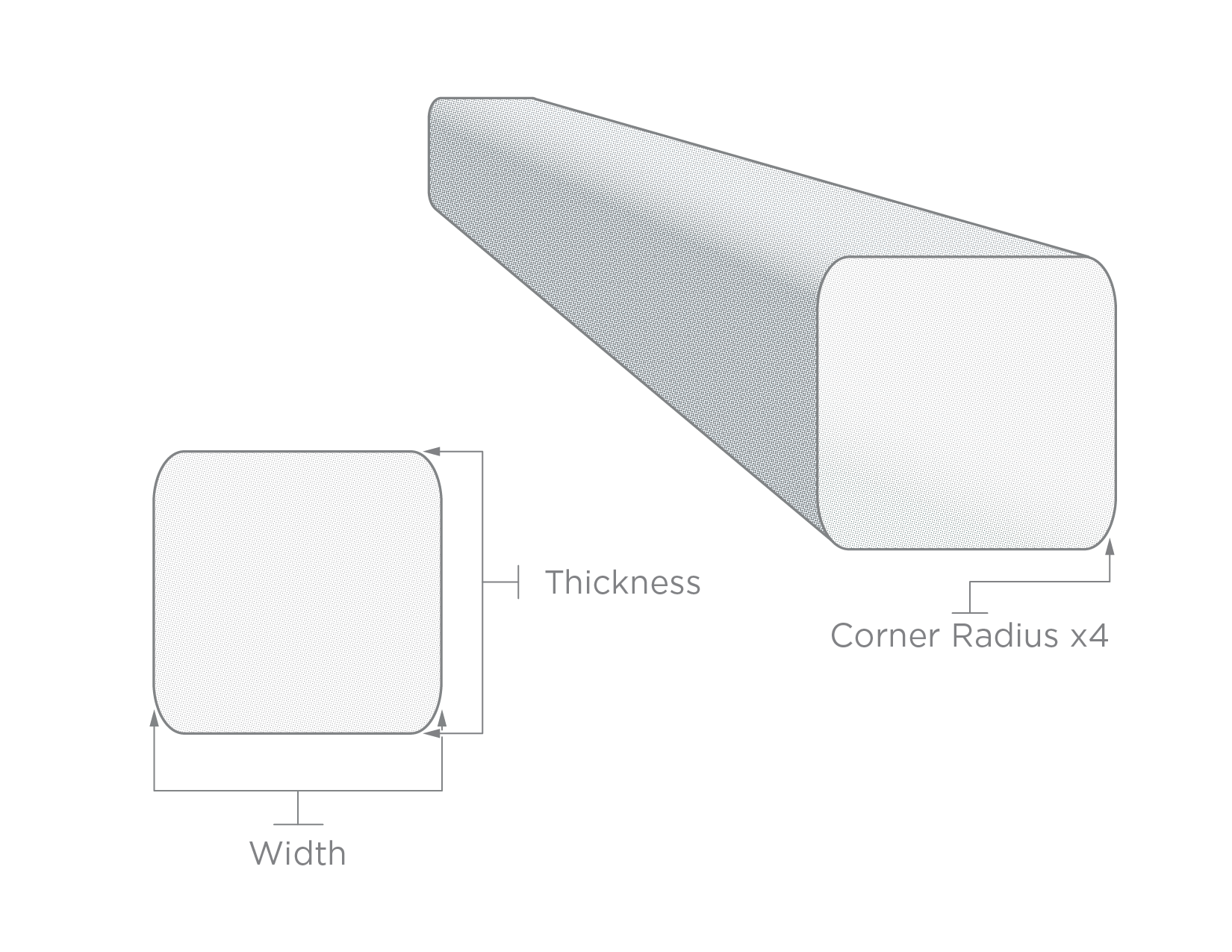

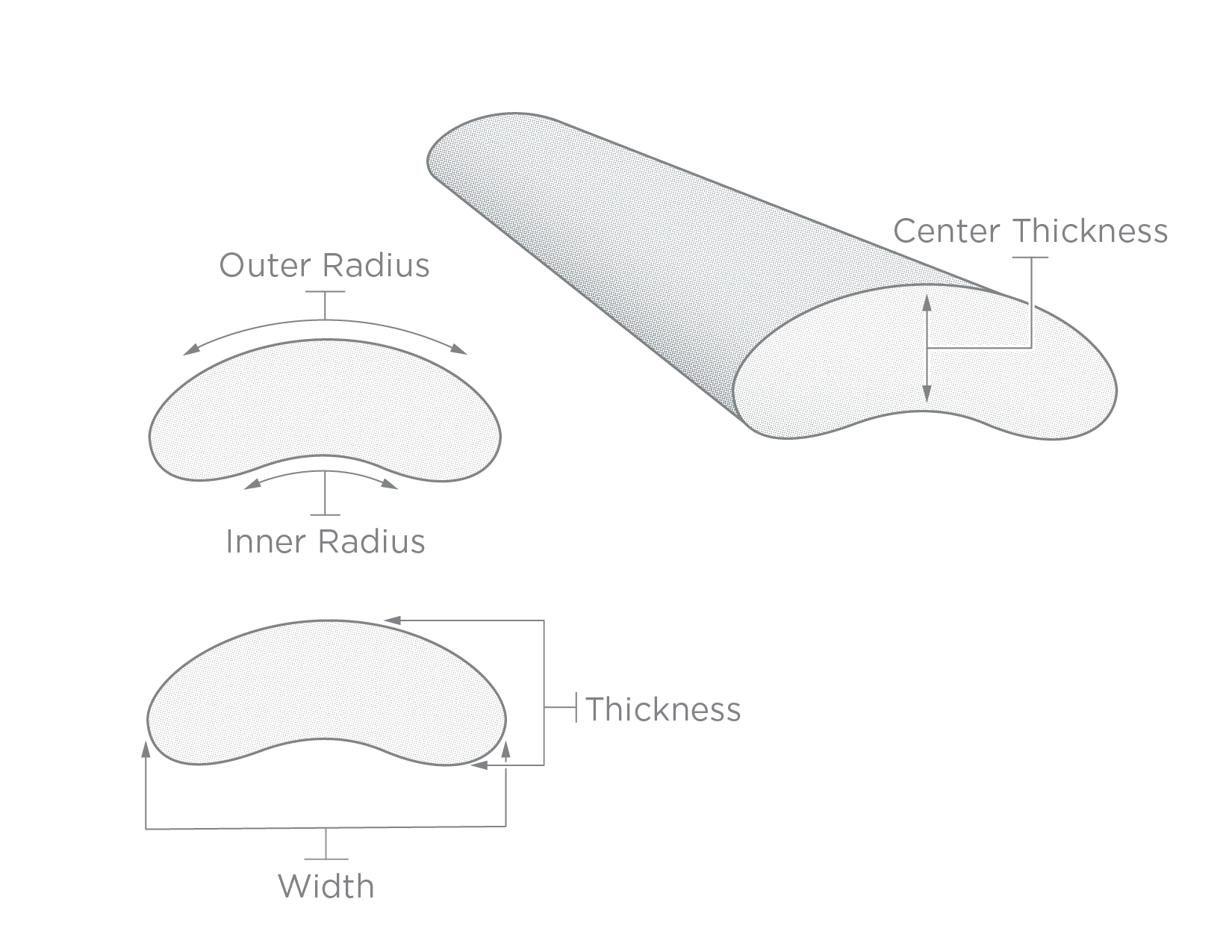

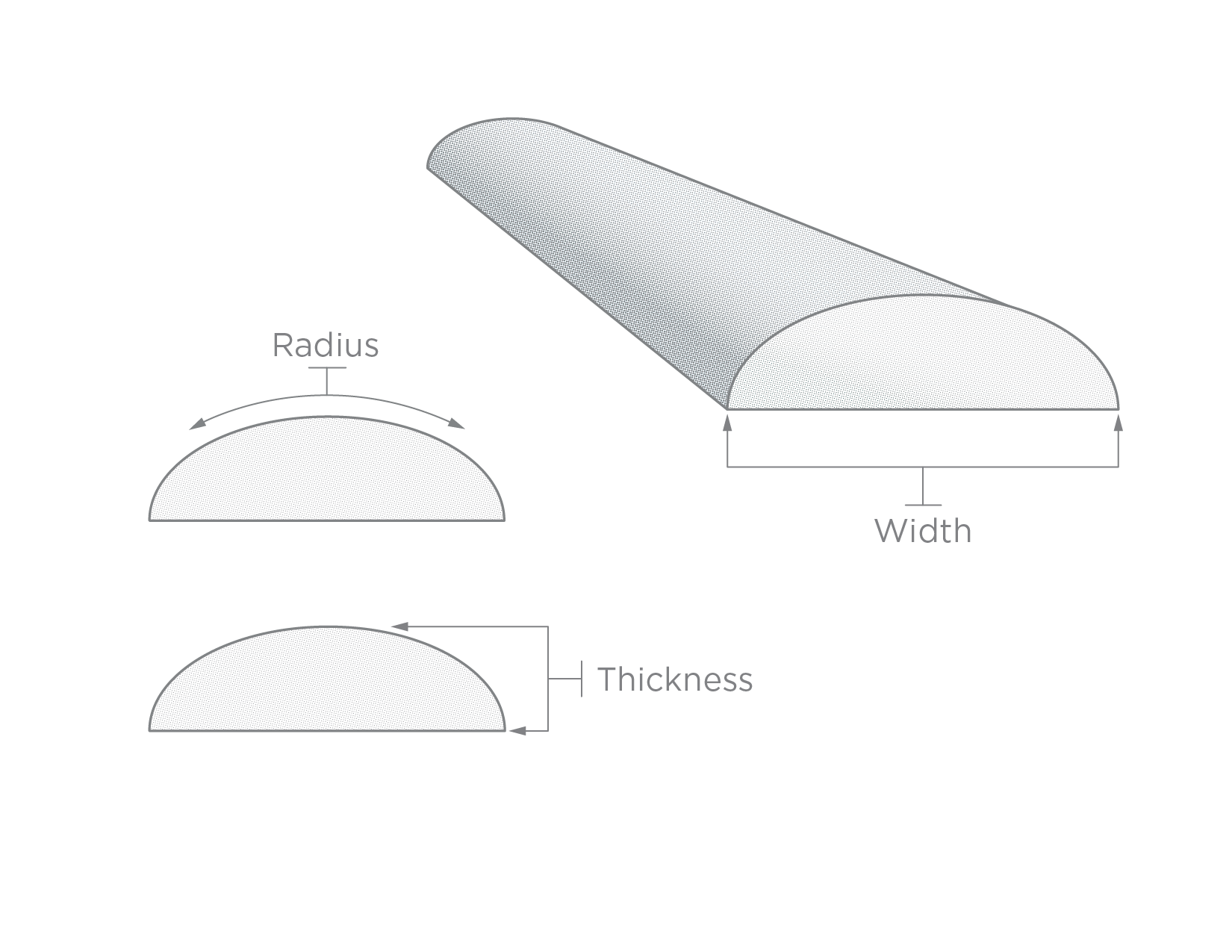

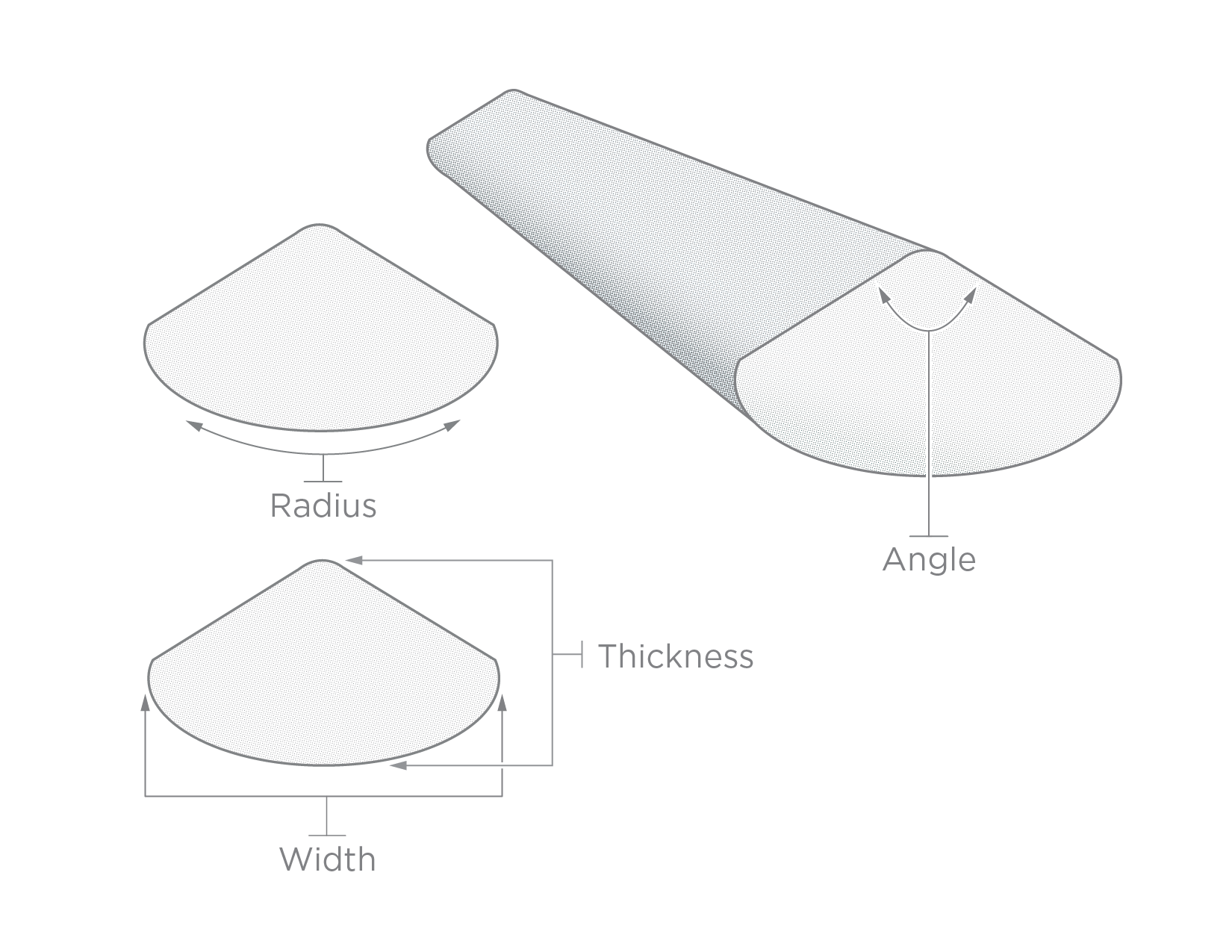

Designing with shaped wire

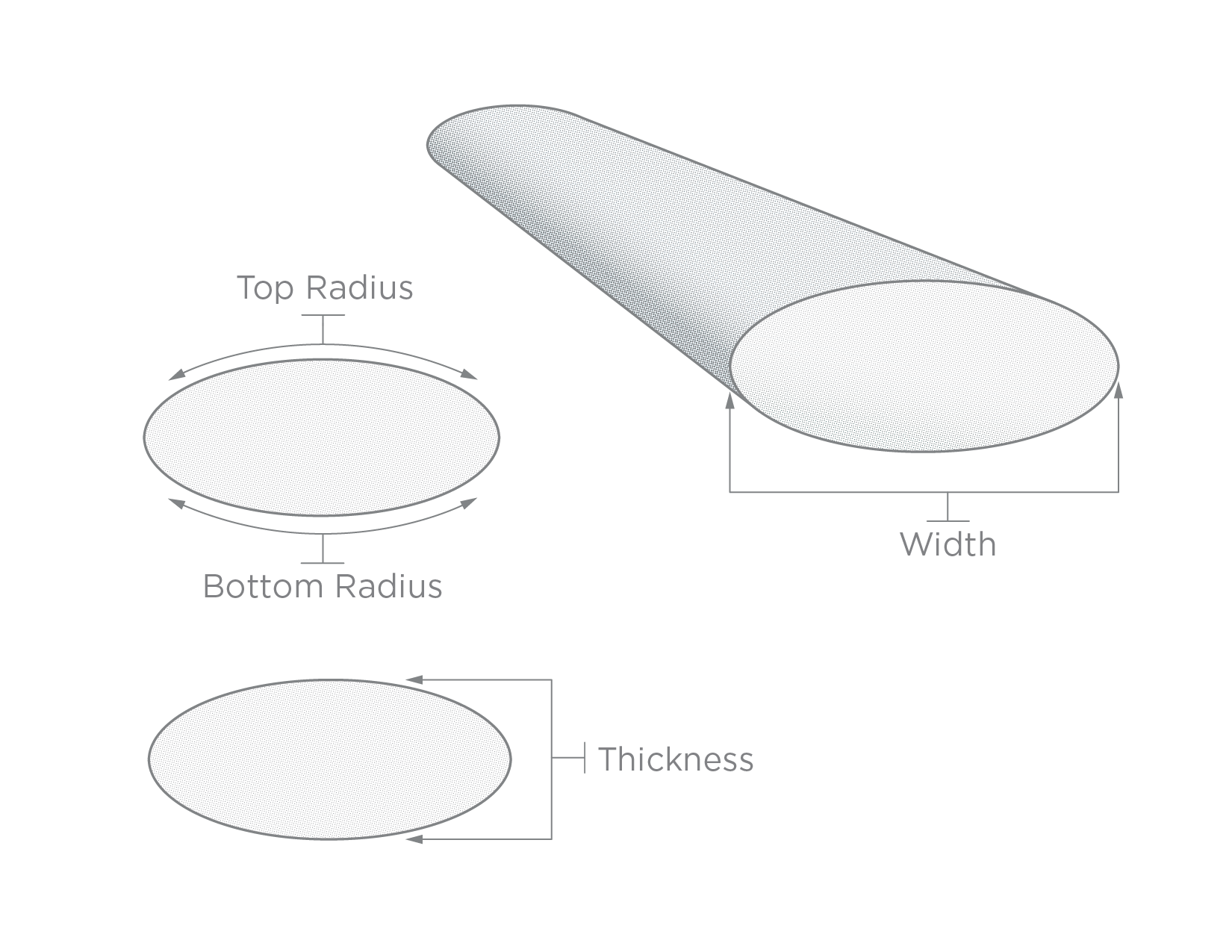

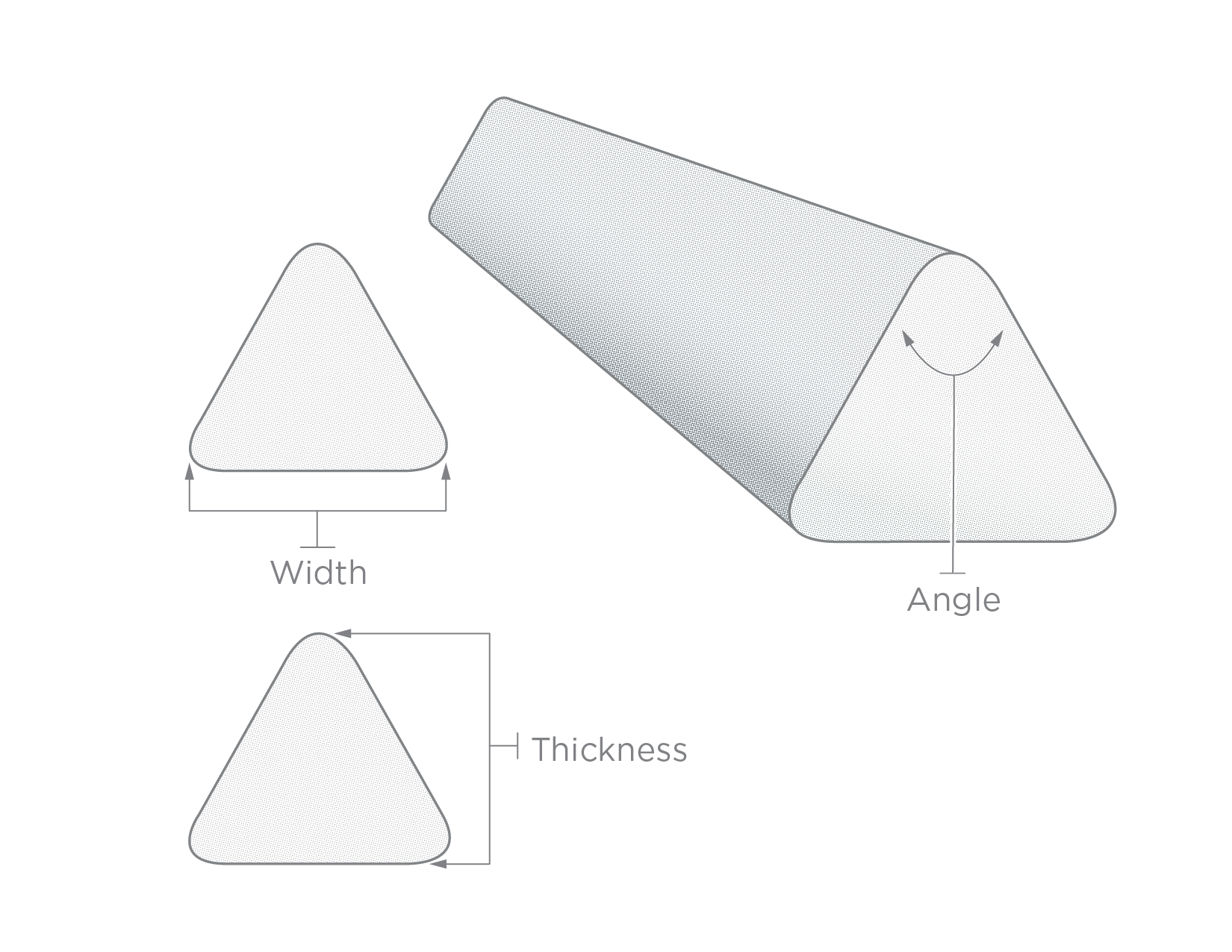

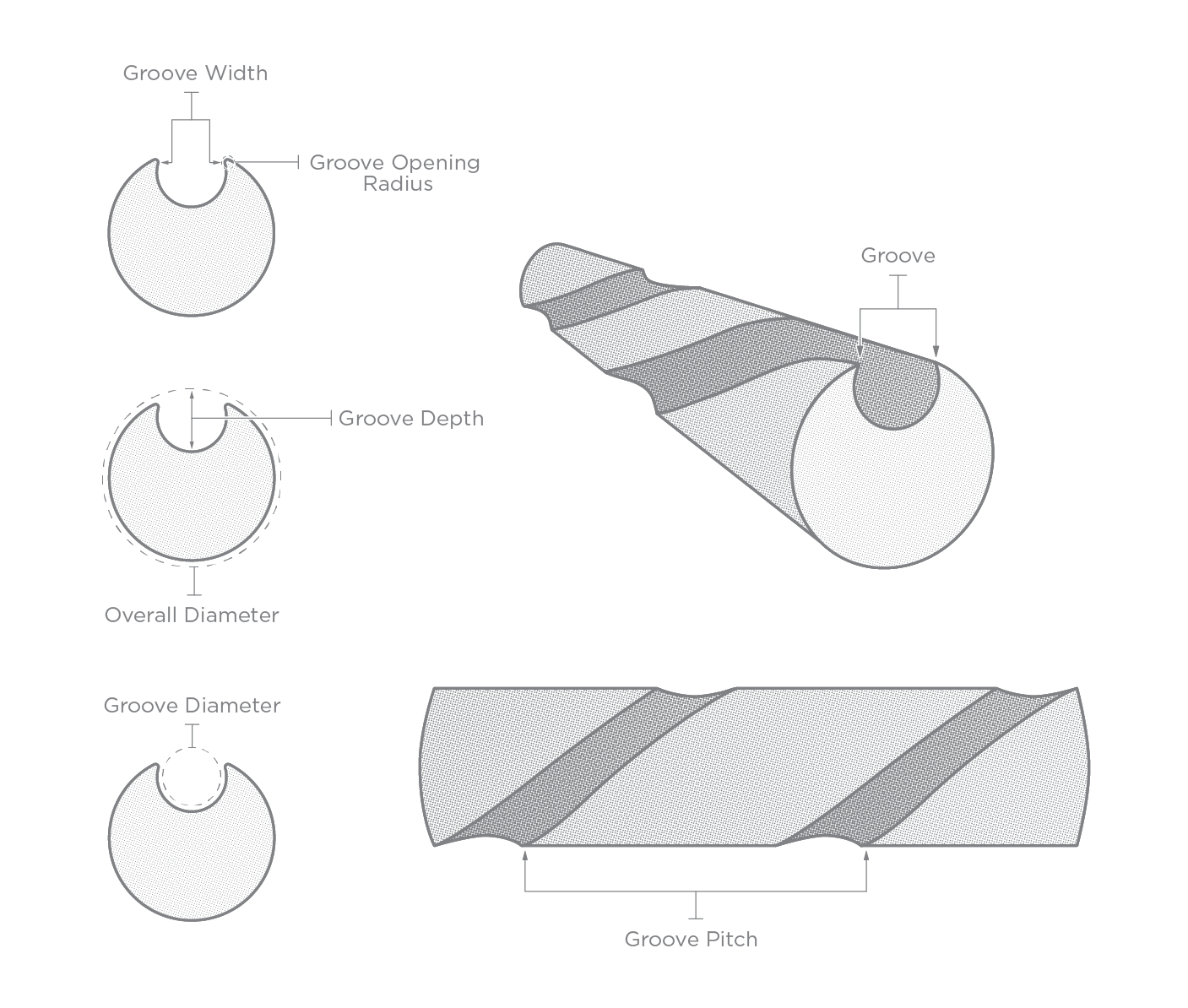

Shaped wire can be manufactured to fit a variety of applications, making it a versatile design component. Given the unusual profiles of shaped wire, our engineering teams use specific terminology and measurements to make tailor products to your specifications. The illustrations below can help guide your conversation with your Sales Representative about what shaped wire can do for your application.

Elliptical wire

Turkshead wire

Crescent wire

D-wire

Pie wire

Triangle wire

Grooved wire