.png)

Mechanical cable

assembly

Custom mechanical assembly

Fort Wayne Metals understands that mechanical assemblies are highly customized products – which is why our engineers will work with you from your initial inquiry through full production. Our computer generated models will help you define concepts and assist your development efforts. All of the assembly work is performed at the same facility where the engineers develop them, allowing them full access to the entire assembly process. We continue to expand our mechanical assembly capabilities. Learn how we can help you. Contact us.

Strands and cables

Cut to length end options:

- Shear

- Electro cut

- Square

- Beaded

- Bead and swage

- Large bead

Please use our cable strand configurator to help you determine the strand or cable that will best suit your needs.

Custom assembly components:

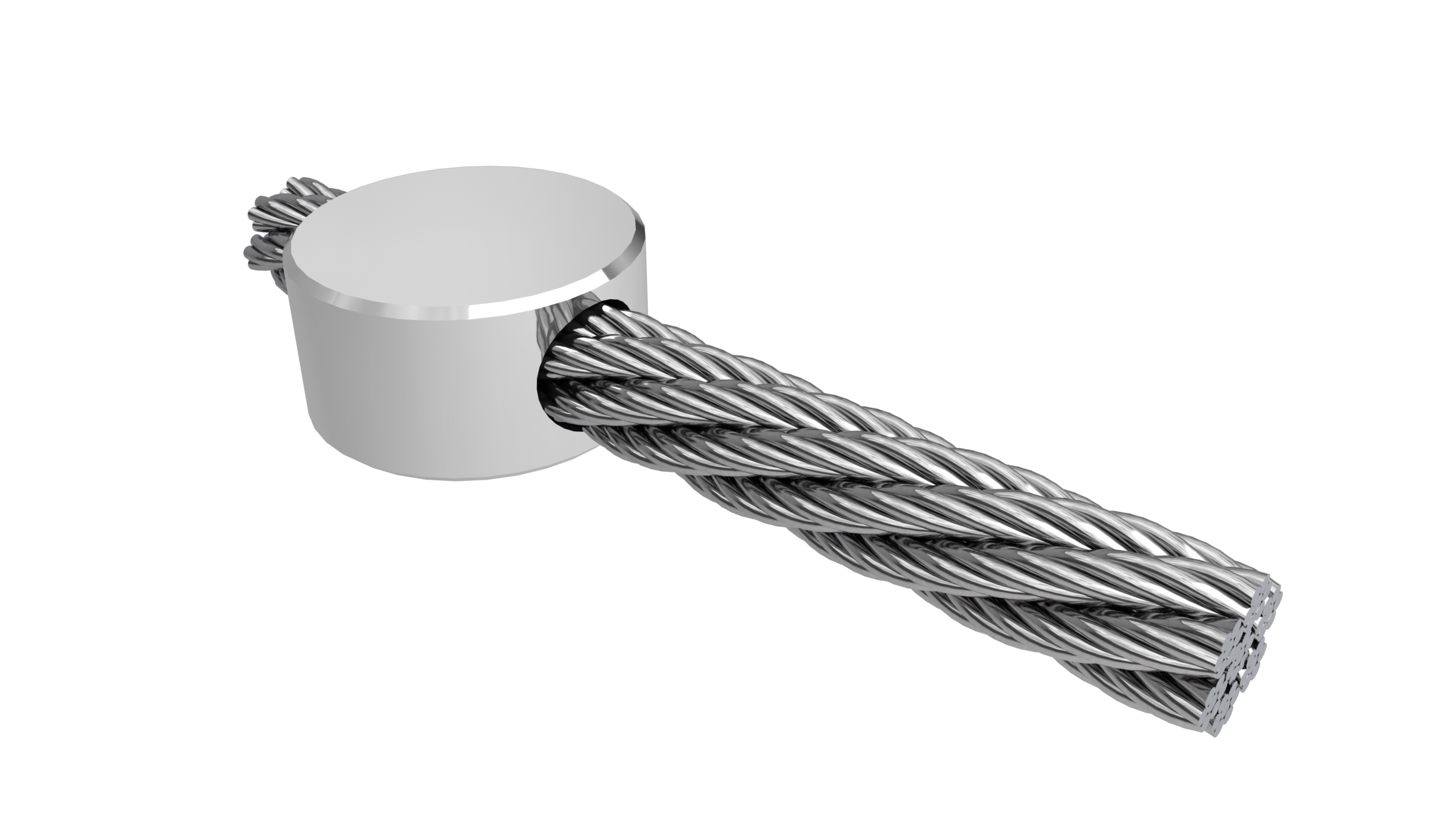

End stops

- Secure attachment point

- Can be attached in the middle of a cable if the pulling is expected in two directions

- Configured to yield a breaking load that approaches the breaking load of the cable to which they are attached

- Close tolerance on swaged diameter to allow for precision placement into a pocket or bore

- Button ends offer the most compact fitting to achieve near full cable breakload

- Fittings are normally factory swaged

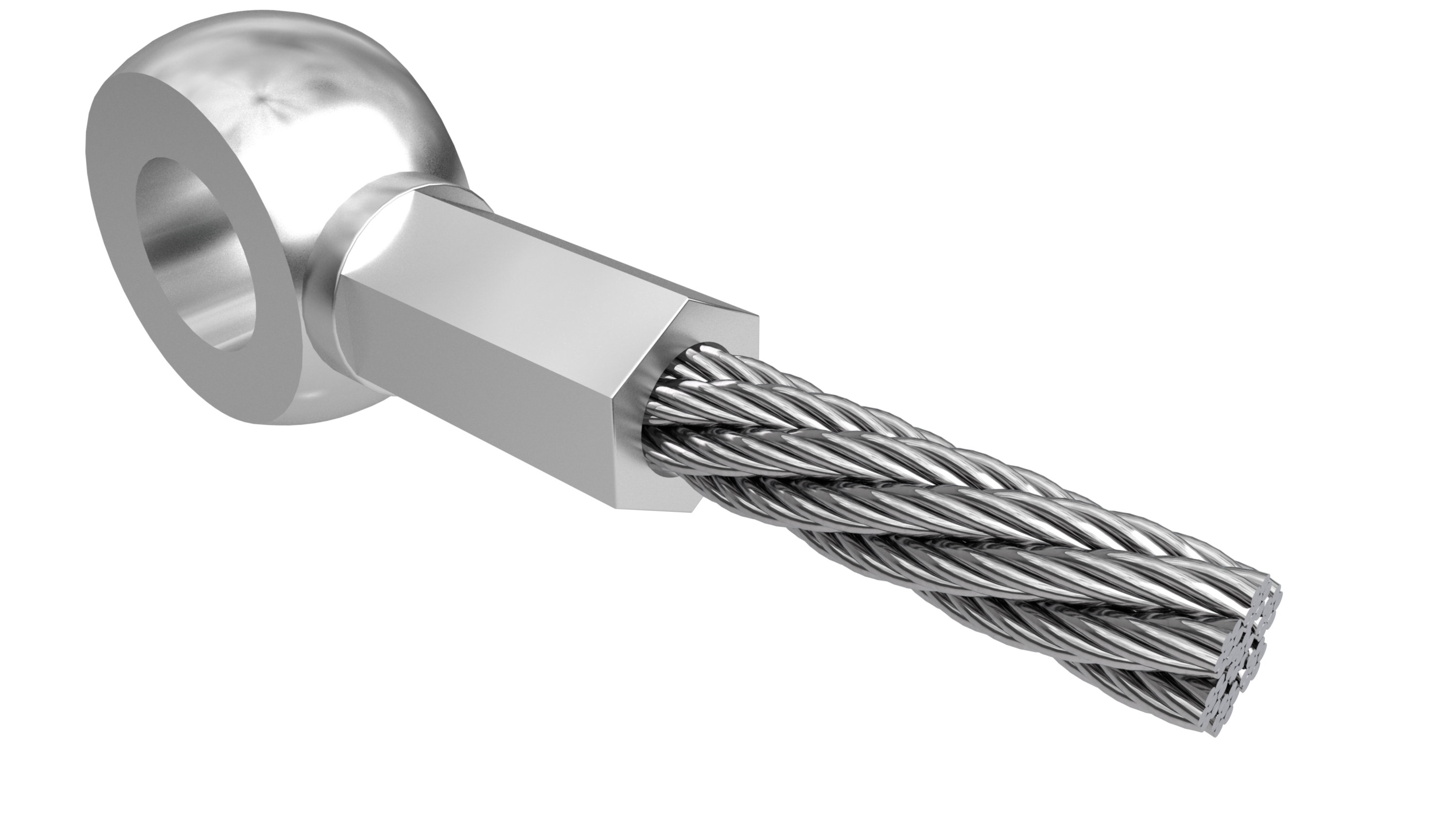

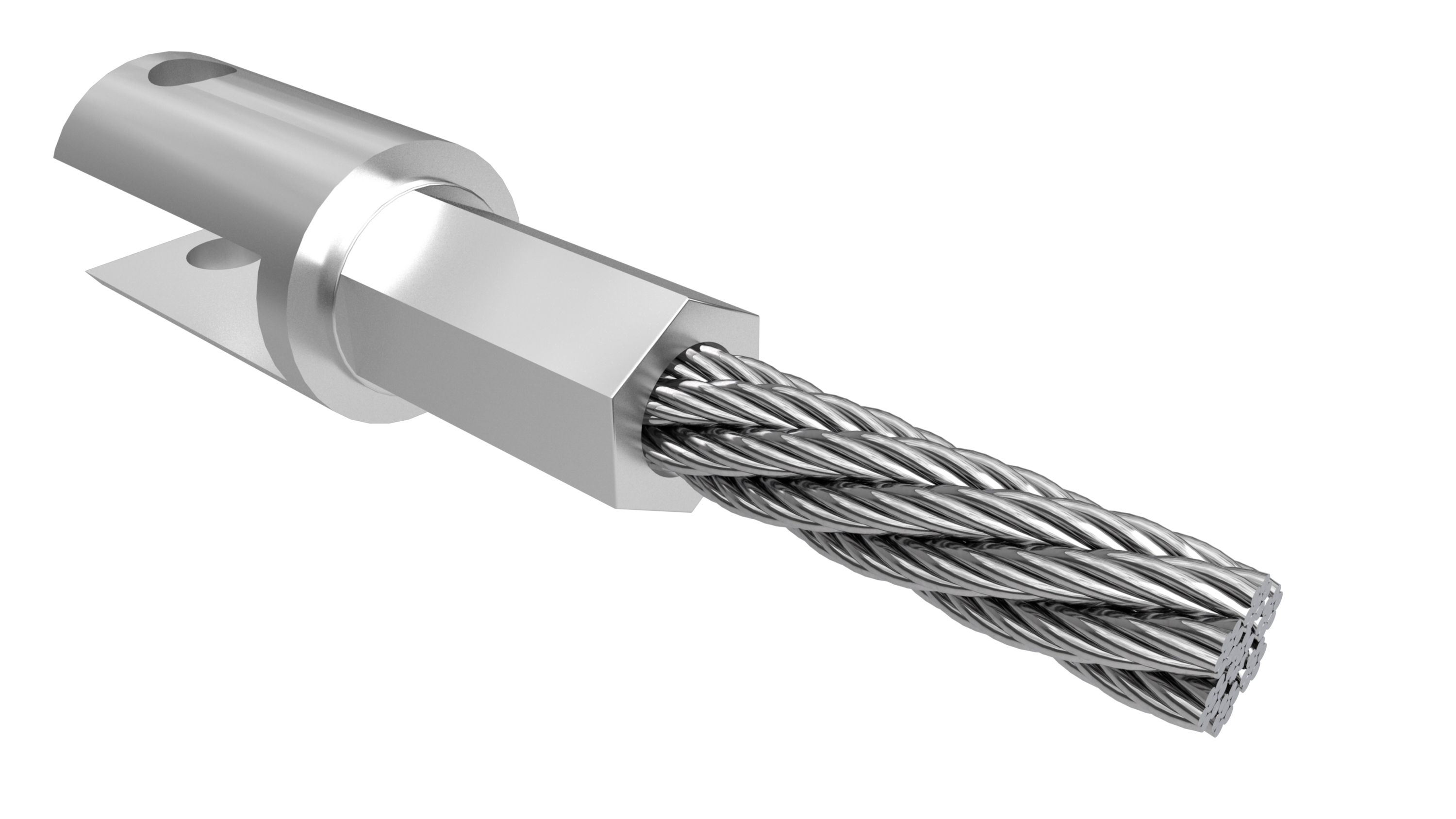

Clevis ends

- Manufactured in a fork or eye configuration

- Attachment point using a cross pin where push and pull may be needed

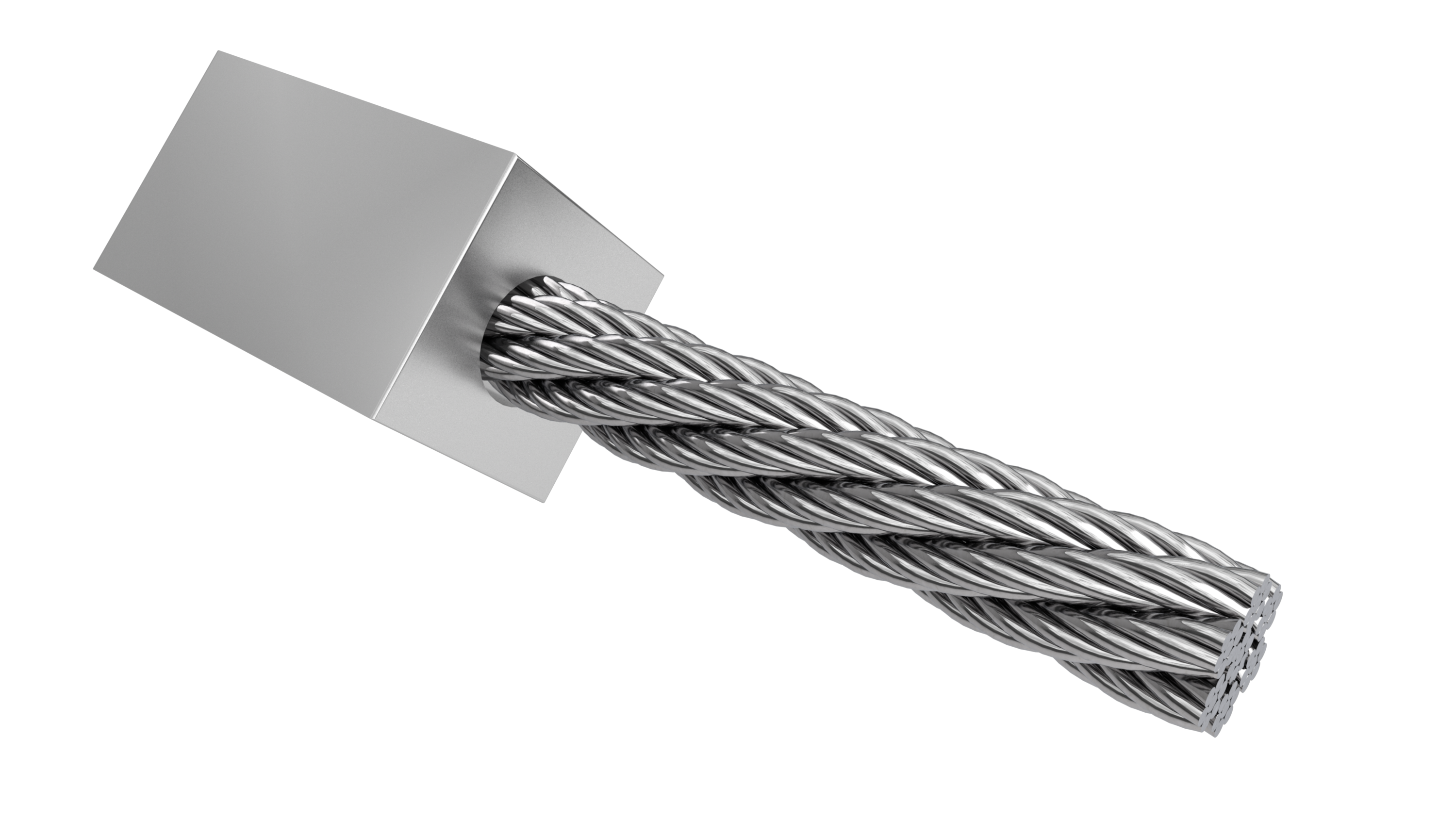

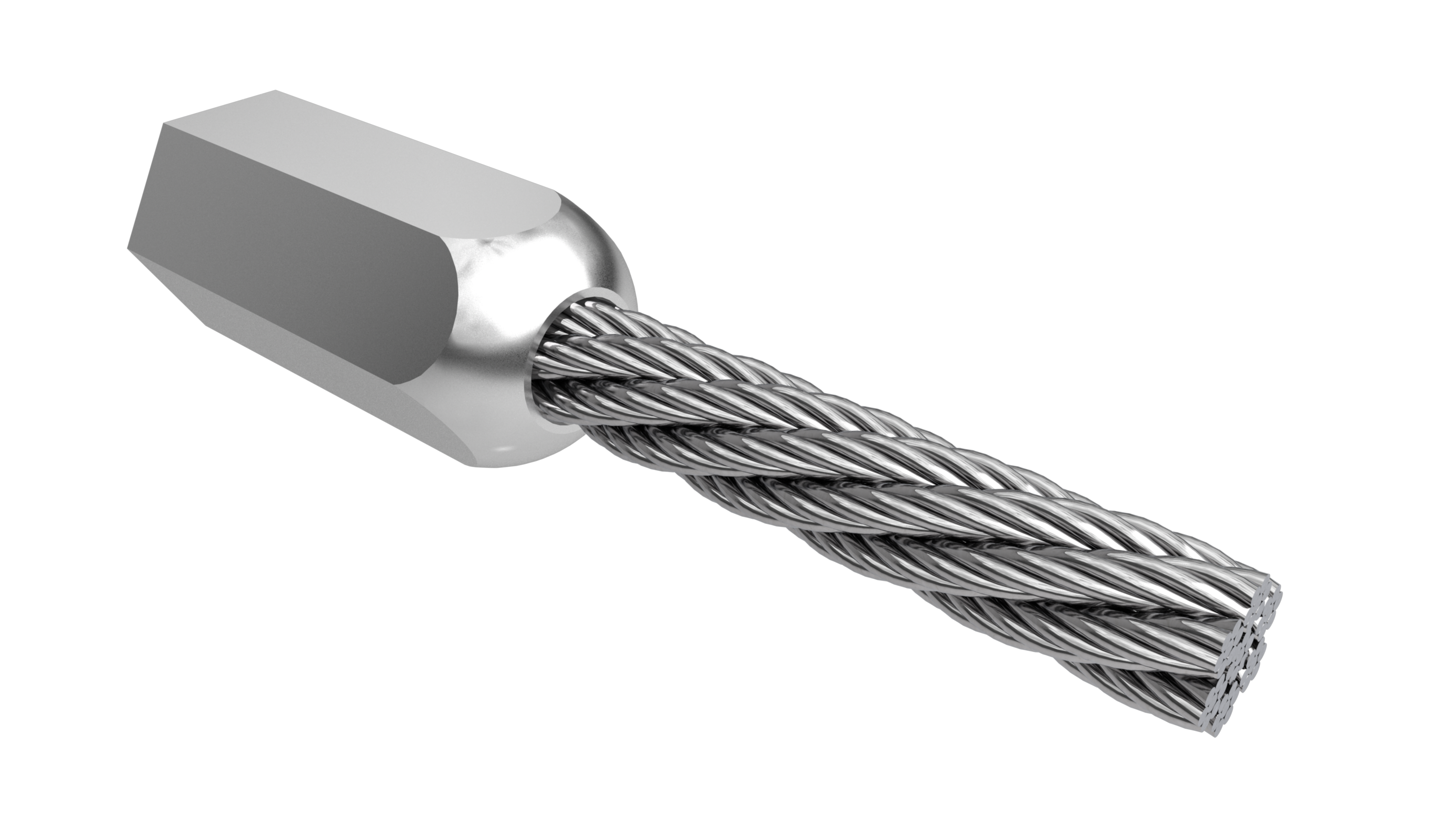

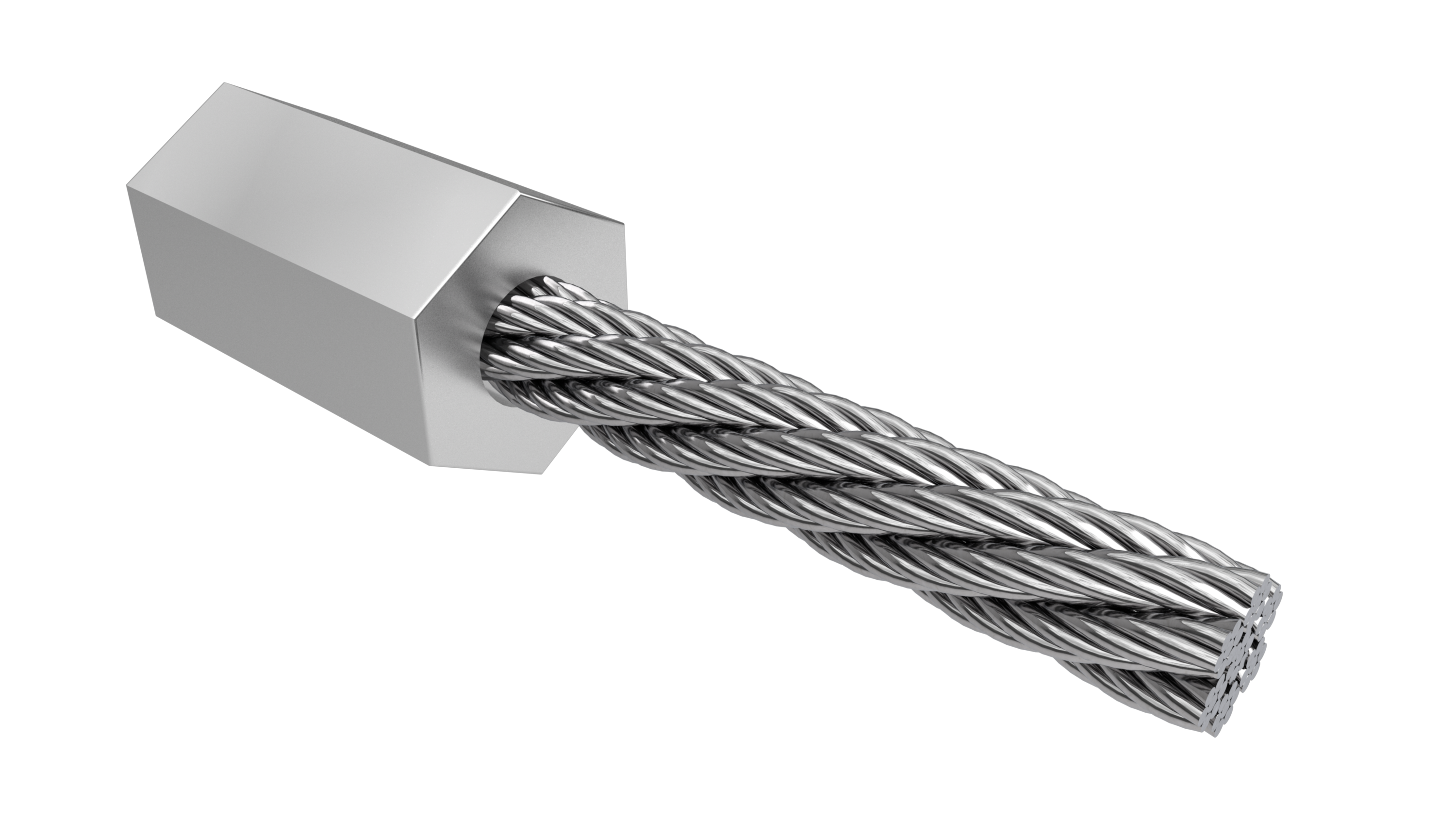

Hexagonal or square end stops

- Economical attachment point

- Larger dimensions

- Can be sold as an accompaniment to cable assemblies with factory applied fittings

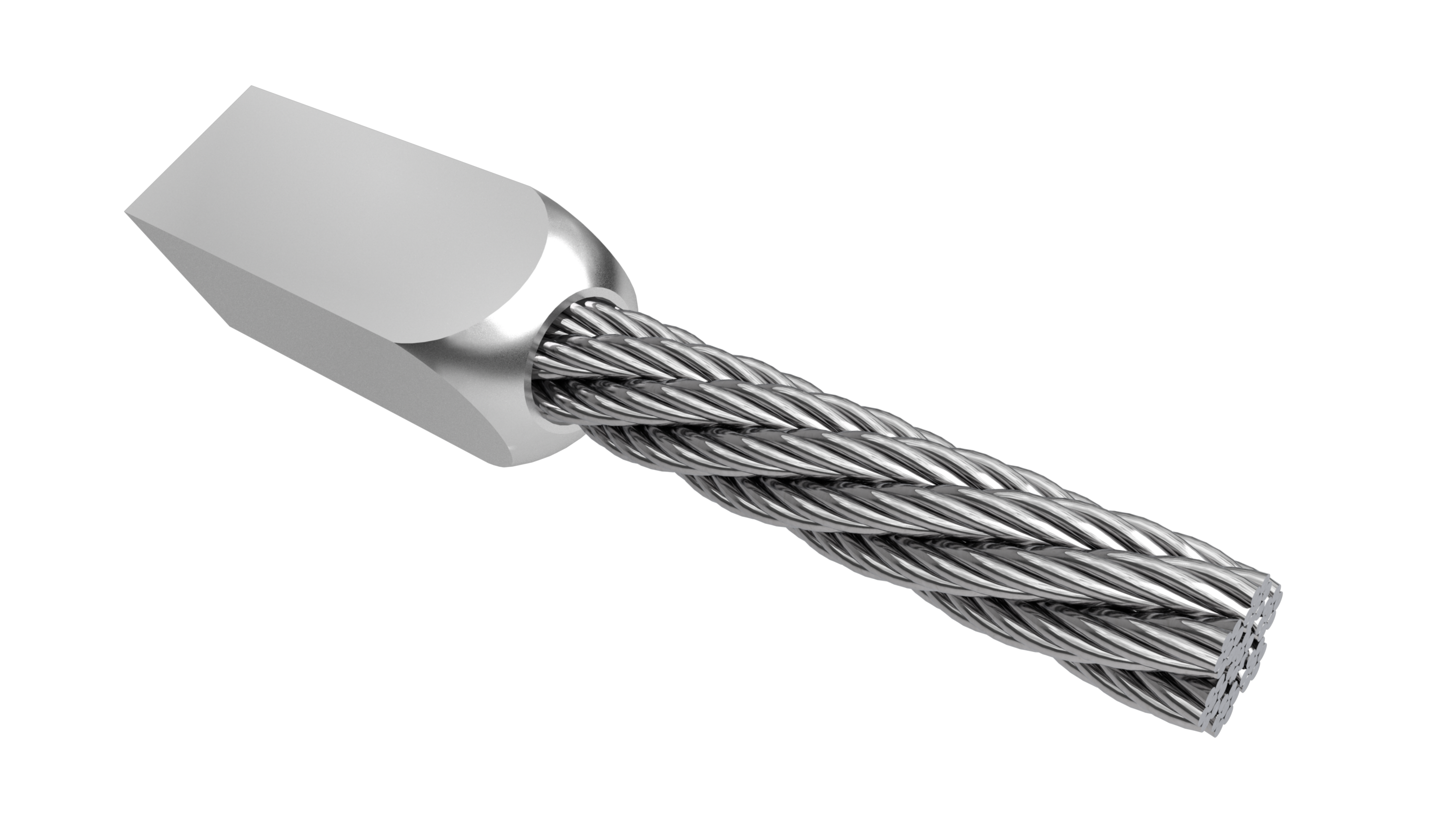

Radiused end stop

- Centers with a bore or pocket

- Holding strength to full breaking load of cable

- Allows for cable rotation and positioning

Spherical fittings:

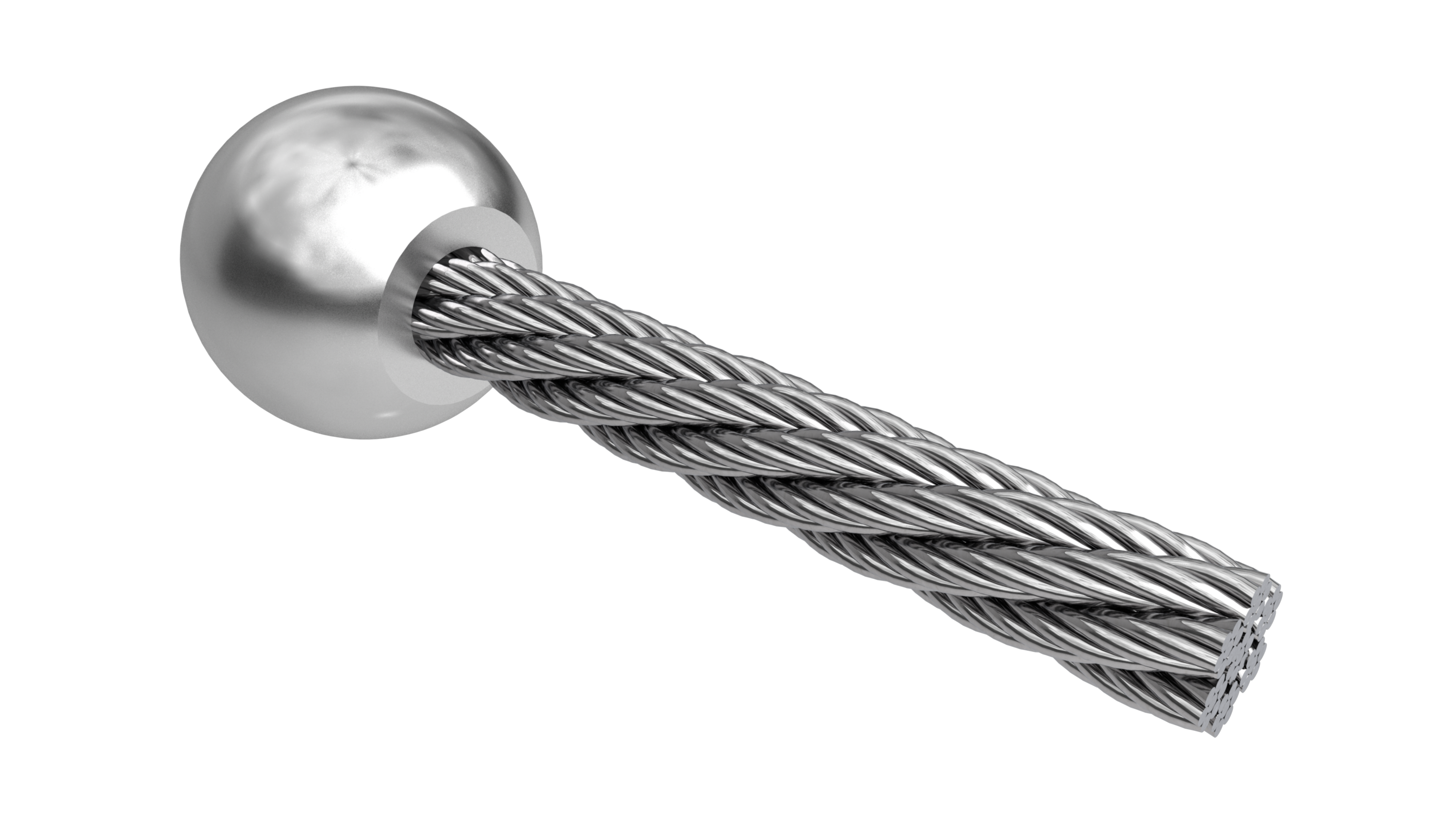

Ball

- Provide 60% of cable breaking load

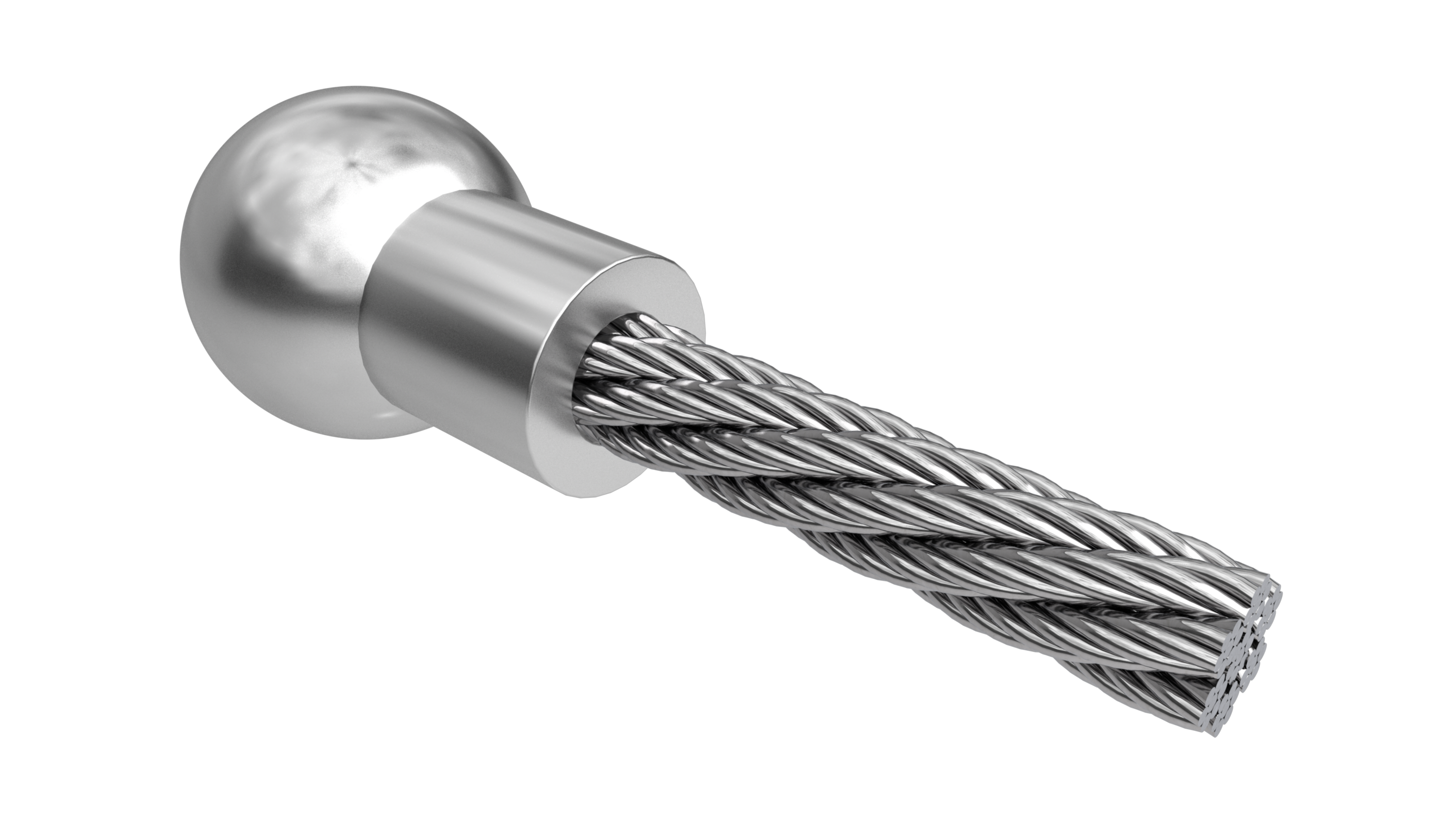

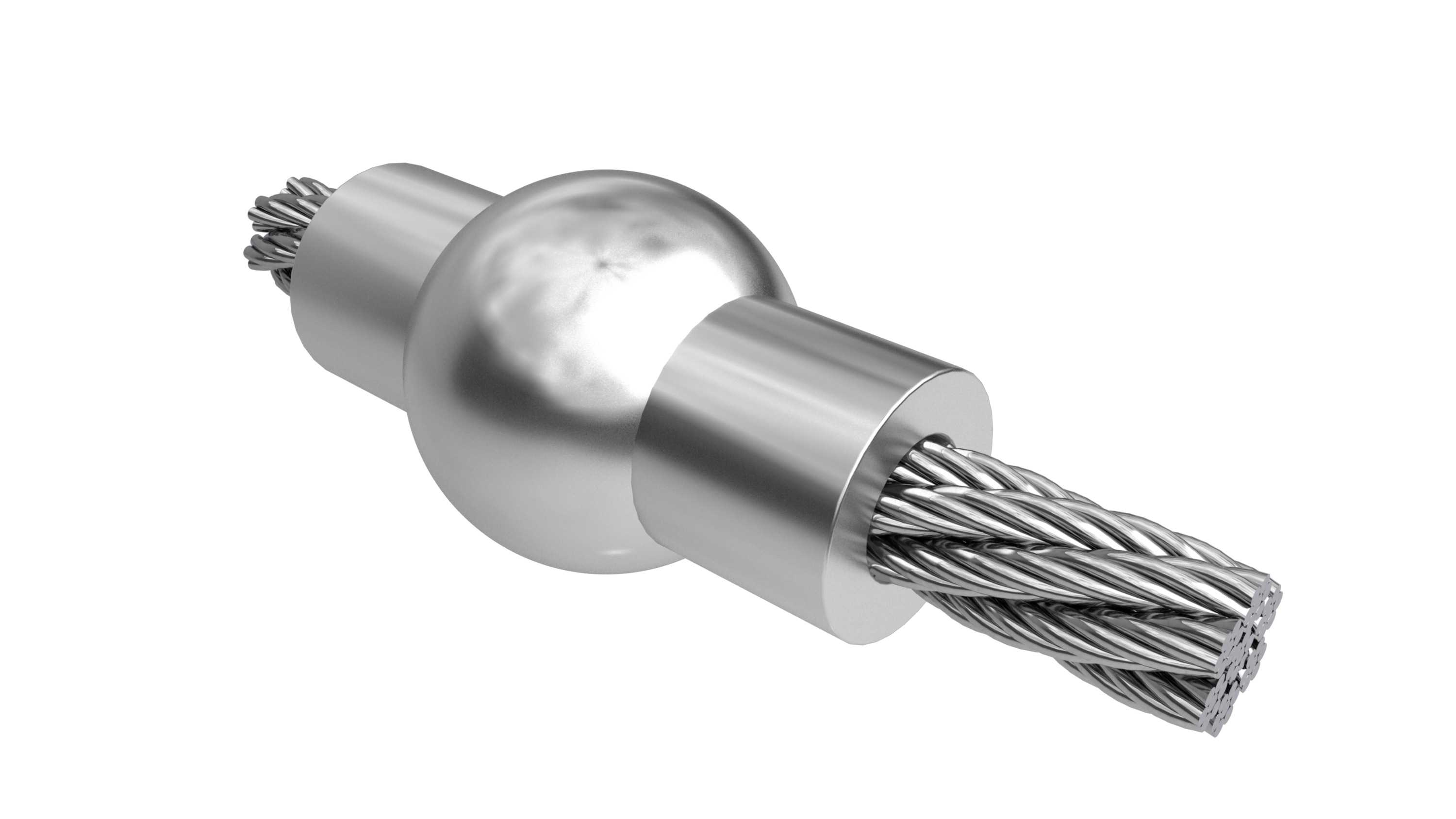

Ball and shank

- Full breaking load of cable

- Allows for attachment within a spherical pocket

- Cable rotation allowed when load is not significant

- Shank provides abrasion protection

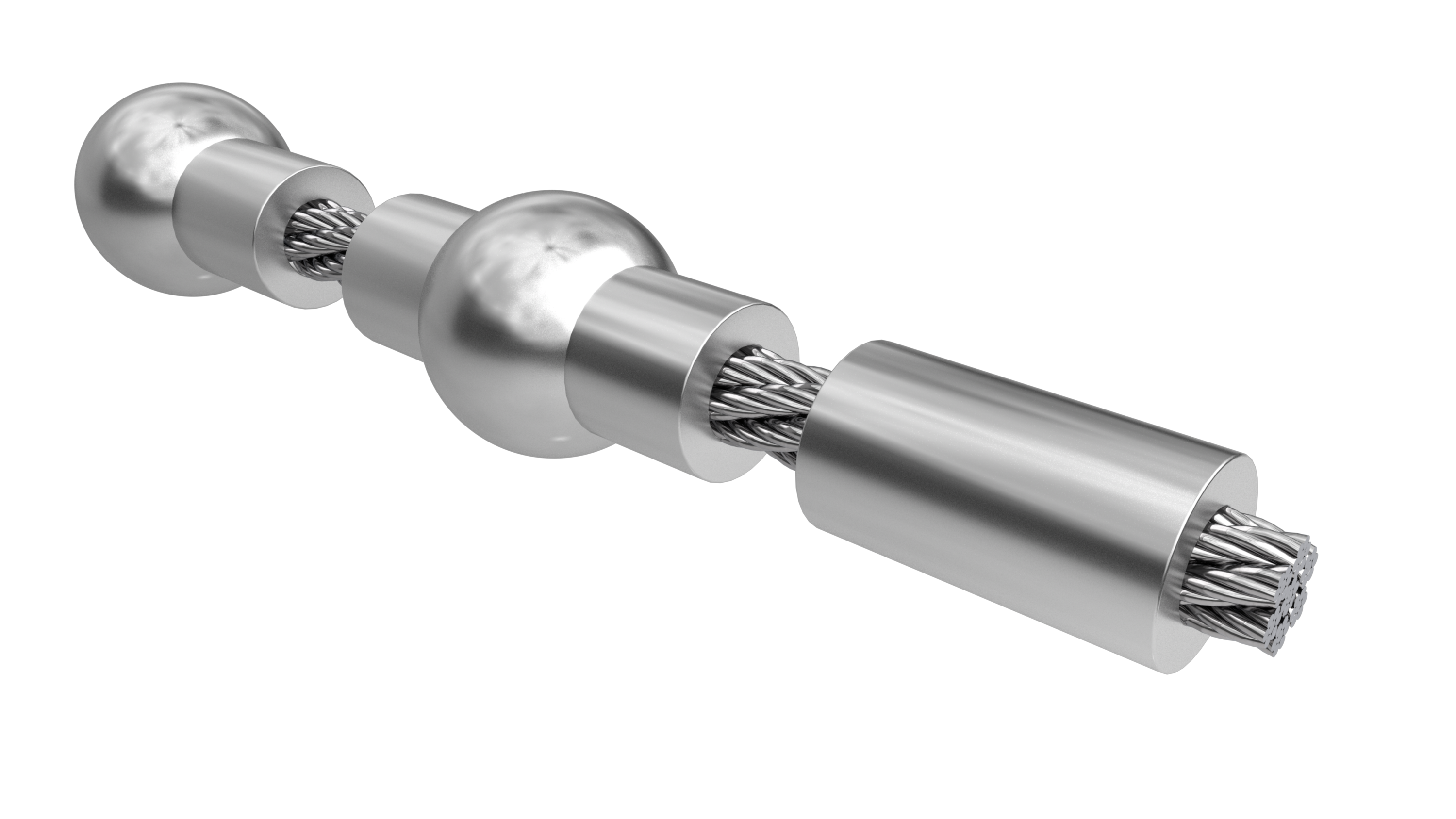

Ball and double shank

- Same properties as ball and shank

- Typically used within a midsection of cable assembly as an attachment point

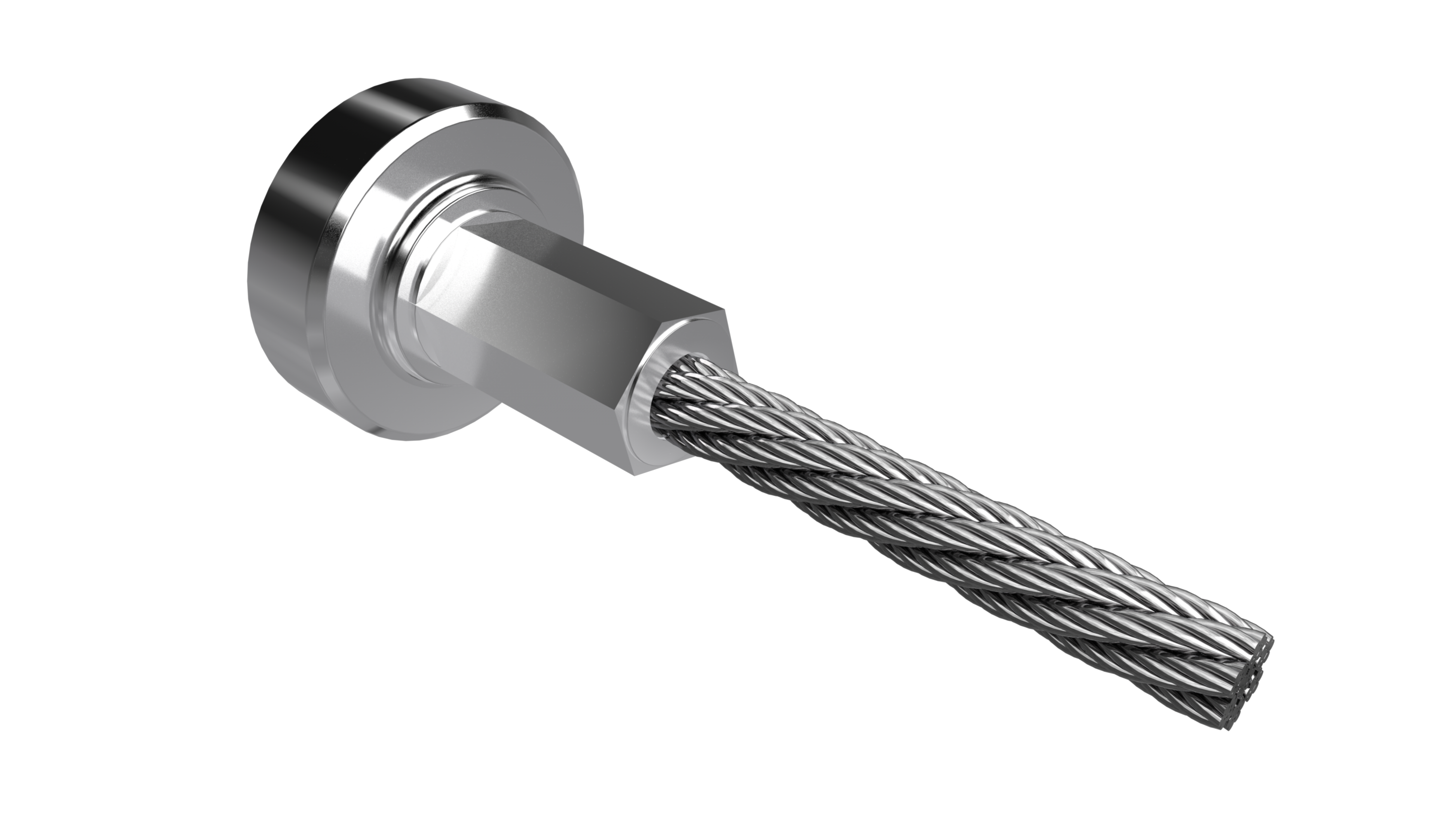

Flanged stop

- Intended for use at end of cable

- Beneficial when cylindrical end stop does not provide enough shoulder

- Eliminates need for washer to prevent pull-through

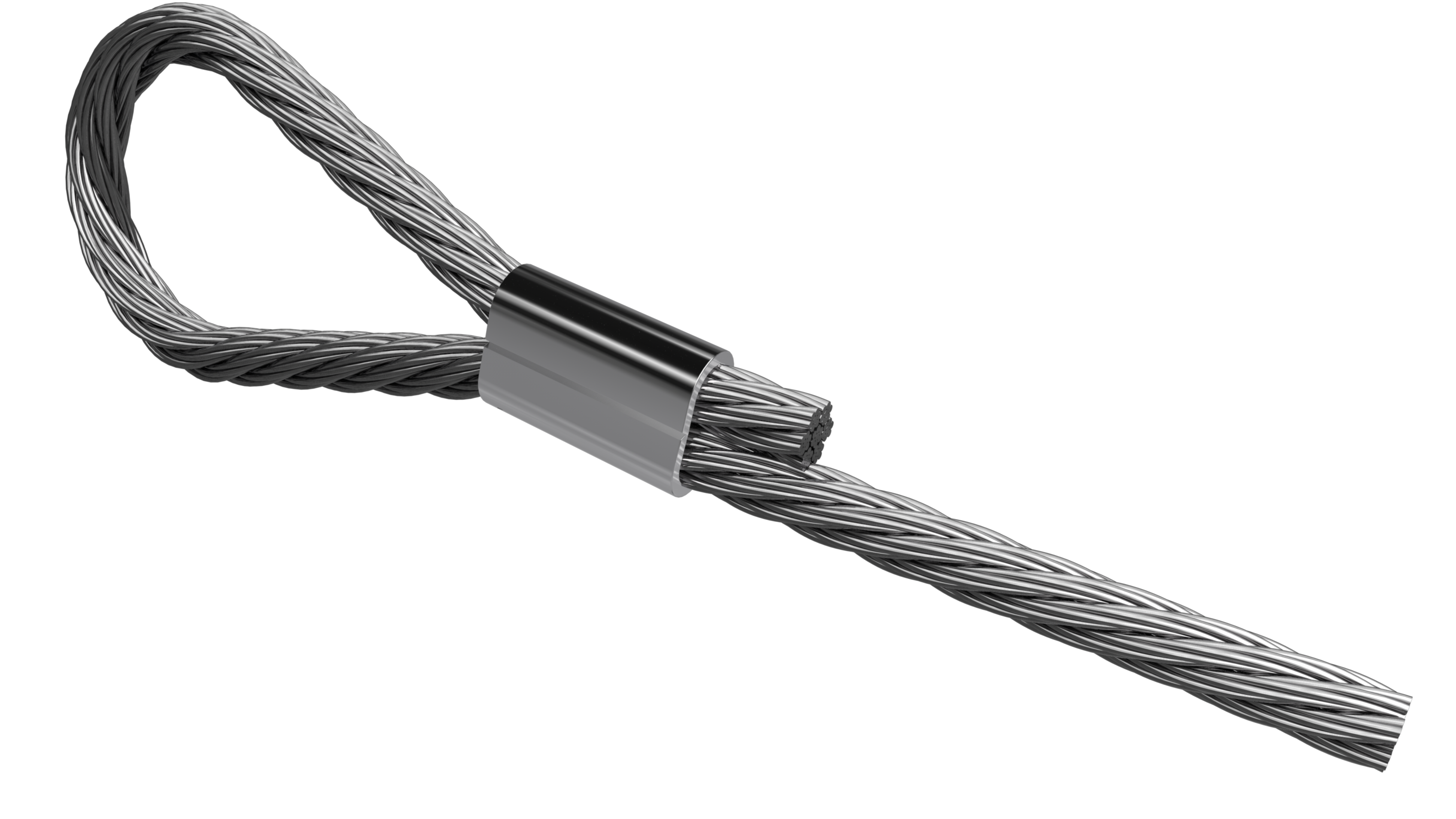

Looped fitting

- Provide attachment point where loop is secured over a pin

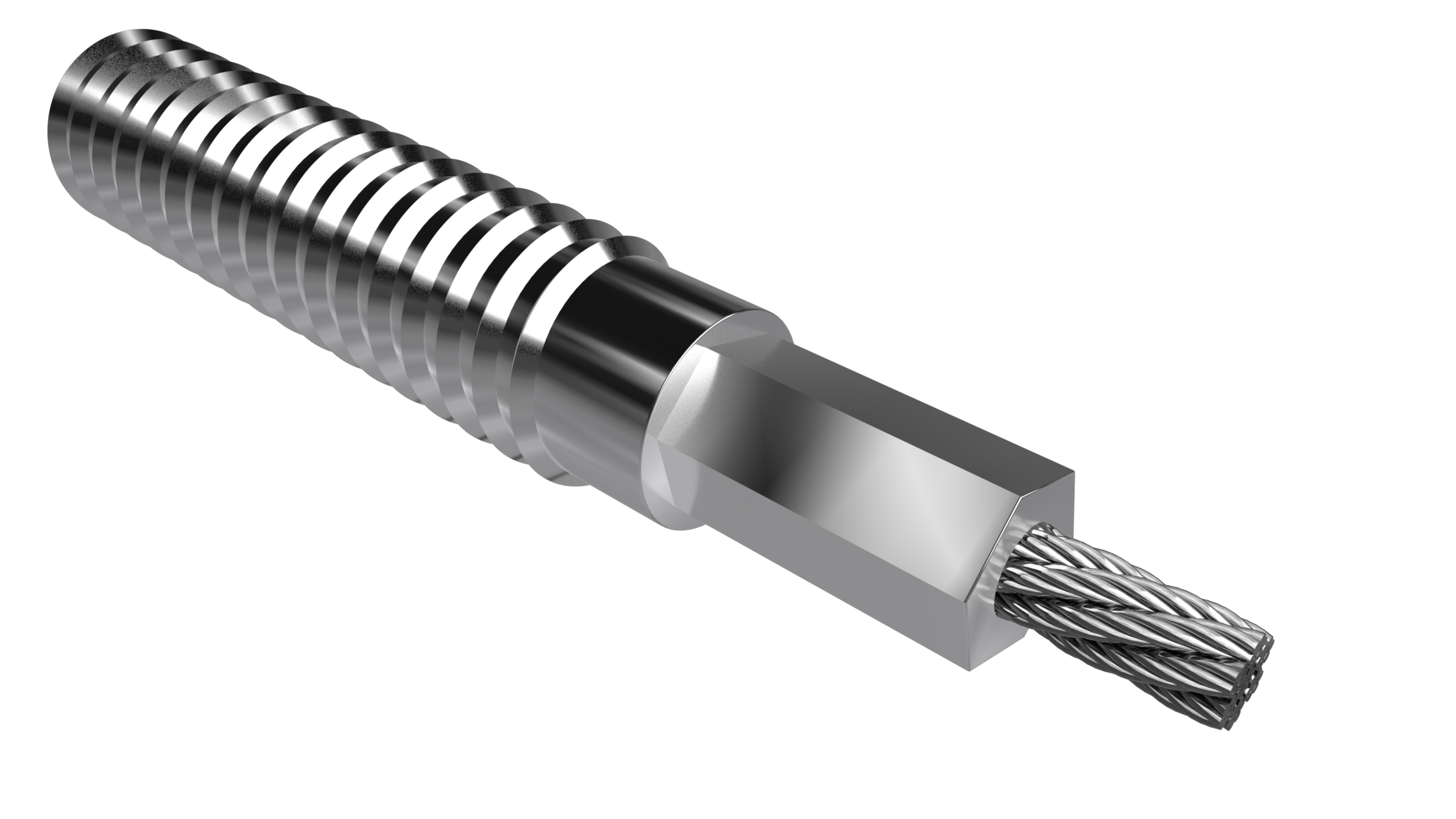

Threaded fittings

- Allow for secure attachment and adjustability

- Shank and thread diameter customizable

- Can be used to precisely set tension

- Adjustable to remove cable slack

Puck fittings

- Patent pending

- Flat top and bottom, resembling a hockey puck

- Superior holding strength

- Tight dimensional tolerances

- Cylindrical sides offer better fit than ball fittings ground to similar geometry

We use various techniques to improve the surface quality of our material and ensure that our material is free of any visible debris or foreign particulates. For more information on our cleaning processes please contact your Fort Wayne Metals Representative.